Types of conveyor rollers to suit your application

Take some time to learn about roller types so you can choose the best one for your applications.

Conveyor rollers are an important part of your conveyor system and are vital to keeping your production line running at its best. Whether you want equipment that moves quickly or extends the life of your conveyor belt, you should take some time to choose the right roller for your job requirements. The article will help you find the best conveyor roller for your application.

Gravity Conveyor Rollers are often the best priced on the market, making them a lot more affordable than others. They can run at a lower speed and also help your conveyor move with less effort, although they can make quite a bit of noise. Typically, both heavy-duty and light-weight gravity rollers are custom designed and machined, showing you can personalize the product to your needs and conveyor system.

![]()

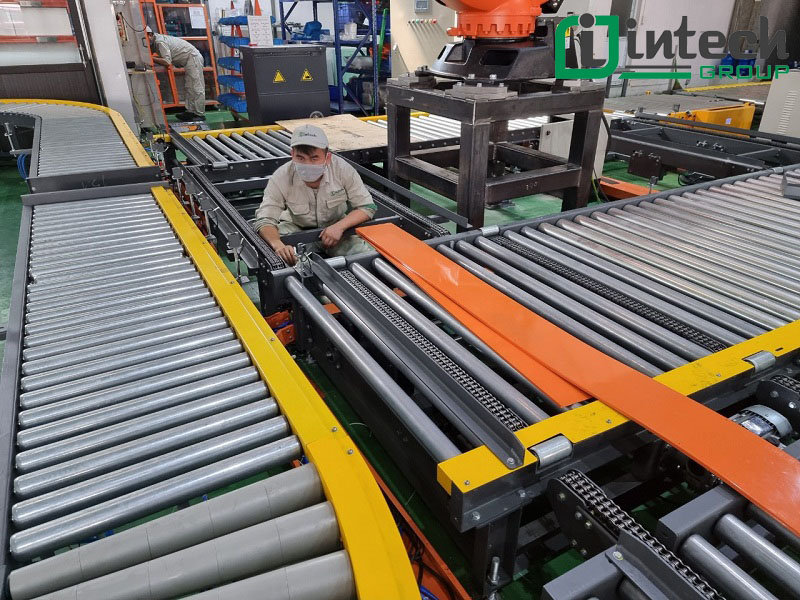

Rollers used in powered conveyors are more affordable as well as innovative. They were developed to reduce the amount of wear on the entire conveyor system as well as extend their own life, and they run extremely quietly with little noise.

Powered roller conveyors are beneficial for automated material handling systems. One of the best features of powered roller conveyor systems is that each roller in this class contains control drums to control the speed and flow of the product in transit.

![]()

Plastic Roller

Plastic conveyor rollers are usually quite inexpensive compared to metal options, and are also best for lighter tons than the sturdy ones. If your production is still in a humid environment then these are the rollers for you. For best use, combine with stainless steel bearings.

![]()

Stainless Steel Roller

It can be said that the most important benefit of stainless steel rollers is that unlike other types, they are much more durable and more flexible. They can be in constant contact with water without rusting, and are also tough enough to handle heavy materials. There are usually many types of tubes and spindles available in stainless steel.

![]()

Now that you have all the important information about these types of conveyor rollers, it's time to make a decision that is sure to be best for you. Consider your budget as well as being reasonable about what you can afford, then consider what will happen on your conveyor system and which roller will work best for you. As soon as you have all the details, it is not difficult to discover the ideal rollers.

Unlike many conveyor roller suppliers, we have experienced engineers and custom design the best product to suit your needs. Our rollers are designed to minimize the three main causes of bearing failure: external contamination, vibration within the bearing, and misalignment. This leads to a longer lifespan.

Material handling is essential to running a successful business in the mining, industrial and marine sectors. This is why choosing a reliable conveyor roller supplier is so important. A reputable company like Intech Group understands the important role of industrial conveyor rollers.

Related Posts:

Rollers in conveyor system gravity

Gravity Conveyor Rollers are often the best priced on the market, making them a lot more affordable than others. They can run at a lower speed and also help your conveyor move with less effort, although they can make quite a bit of noise. Typically, both heavy-duty and light-weight gravity rollers are custom designed and machined, showing you can personalize the product to your needs and conveyor system.

Rollers in conveyor systems are powered

Rollers used in powered conveyors are more affordable as well as innovative. They were developed to reduce the amount of wear on the entire conveyor system as well as extend their own life, and they run extremely quietly with little noise.

Powered roller conveyors are beneficial for automated material handling systems. One of the best features of powered roller conveyor systems is that each roller in this class contains control drums to control the speed and flow of the product in transit.

Plastic Roller

Plastic conveyor rollers are usually quite inexpensive compared to metal options, and are also best for lighter tons than the sturdy ones. If your production is still in a humid environment then these are the rollers for you. For best use, combine with stainless steel bearings.

Stainless Steel Roller

It can be said that the most important benefit of stainless steel rollers is that unlike other types, they are much more durable and more flexible. They can be in constant contact with water without rusting, and are also tough enough to handle heavy materials. There are usually many types of tubes and spindles available in stainless steel.

Which type is right for you?

Now that you have all the important information about these types of conveyor rollers, it's time to make a decision that is sure to be best for you. Consider your budget as well as being reasonable about what you can afford, then consider what will happen on your conveyor system and which roller will work best for you. As soon as you have all the details, it is not difficult to discover the ideal rollers.

Intech manufactures and supplies prestigious and professional conveyor rollers

Unlike many conveyor roller suppliers, we have experienced engineers and custom design the best product to suit your needs. Our rollers are designed to minimize the three main causes of bearing failure: external contamination, vibration within the bearing, and misalignment. This leads to a longer lifespan.

Material handling is essential to running a successful business in the mining, industrial and marine sectors. This is why choosing a reliable conveyor roller supplier is so important. A reputable company like Intech Group understands the important role of industrial conveyor rollers.

Related Posts:

- Special grain conveyor system in food processing

- How to choose the best conveyor system for fragile materials

- What is Conveyor Belt Connector and popular effective methods today