Guide to automated warehouse systems

To compete in today’s manufacturing world, efficiency is essential to the process and to achieve this goal, nothing helps improve efficiency better than an automated warehouse.

We have moved far beyond the labor-intensive world of manufacturing. In the past, your success was largely determined by the size of your workforce. Today, more and more companies are using automated warehouse systems to streamline production and increase efficiency. The changing of the guard has come with the advancement of technology and automation. Manufacturers are starting to tap into these for convenience and to gain a significant advantage over their competitors.

Let’s explore how warehouse automation works and how manufacturers can use automated warehouse systems to put themselves and their employees in a better position to succeed.

Let’s explore how warehouse automation works and how manufacturers can use automated warehouse systems to put themselves and their employees in a better position to succeed.

What is warehouse automation?

Moving inventory in and out of a warehouse and then delivering it to customers with little or no human assistance is called warehouse automation. Businesses that implement automated warehouse systems into their operations can eliminate labor-intensive tasks including manual data entry and analysis as well as repetitive physical work.

A real-world example of automation in action is when warehouse workers load heavy and bulky packages onto autonomous mobile robots. The robots then move inventory from one end of the warehouse to the other, with the final destination of the inventory being the shipping area.

During the inventory movement, the software records the movement of supplies, updating all records. Therefore, the use of these robots improves the speed, reliability, accuracy, and frequency of this task. Automated warehouses start with a warehouse management system (WMS), data collection, and inventory control. Although there is a significant upfront cost, the immediate and long-term benefits are well worth it.

By integrating robotics and artificial intelligence (AI) into your warehouse floor, you will reduce human error and improve overall operations. The incredible benefits and exciting future of warehouse automation are limitless.

Automated Warehouse Systems in use today

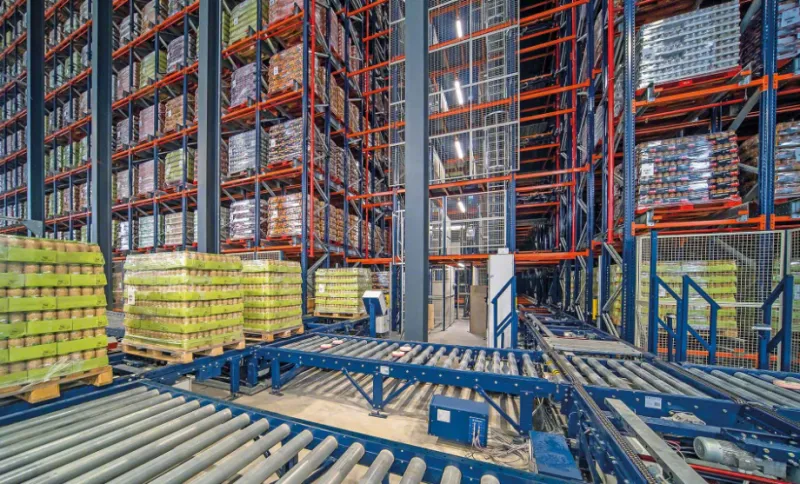

Automated warehouse systems or automated storage and retrieval systems (AS/RS) are GTP technologies that use vehicles, conveyors, and cranes to efficiently move inventory from warehouse to storage locations in the warehouse.

- Conveyor Systems

One of the oldest automated warehouse technologies is the conveyor system. Simply put, conveyors move materials along the assembly line to various workstations such as sorting areas, packing areas, and shipping areas.

- Voice Picking and Voice Tasking

This automated warehouse system requires employees called pickers to use wireless headsets to communicate with taskers to coordinate picking tasks and movements. Voice Picking brings communication technology into the warehouse order picker process.

- Pick-To-Light System

This system uses barcodes and LEDs to help employees locate items needed to fulfill orders. Pick-to-light systems reduce human effort by reducing walking time and increase productivity by helping to locate items faster.

- Sorting Systems

Sorting systems used in warehouses can access the right location and appropriate bins by using various technologies to identify and classify items, guiding them to the picking area, packing station, or processing returns.

- Drones

Usually drones are used for inventory management. They are equipped with barcode scanners to count inventory and alert employees when items need to be replenished or misplaced.

- Collaborative Mobile Robots

These robots work alongside humans to improve productivity and accuracy in picking while guiding workers through the picking process.

Automated Distribution in Warehouses

Automated distribution includes all systems in place to increase efficiency in the warehouse related to distribution.

- Receiving

Mobile devices can be used to quickly collect data from your warehouse receiving area. Integrated software collects, processes, and stores the necessary data that impacts both downstream and upstream automated workflows.

- Returns

When processing returns, automated sortation systems combined with equipment such as conveyors can automate the returns process. The system can sort products for return to the warehouse shelves or storage areas.

- Putaway

Putaway is the process of moving products from receiving to storage. Automating physical and digital warehouse processes makes warehousing more accurate and efficient. Automation can also help facilitate cross-docking.

- Select

Manual picking is by far the most expensive warehouse activity. Did you know that travel time in the warehouse accounts for up to 50% of total man-hours? Automated GTP systems and mobile robots dramatically increase the efficiency and speed of inventory movement.

- Sort

When you are sorting and consolidating inventory in the warehouse, it can be cumbersome, confusing, and time-consuming. Fortunately, automated sorting systems and AS/RS significantly improve inventory quality control and accuracy.

- Replenish

Automated inventory tracking triggers an automatic requisition when an inventory item reaches a specific par value and flags it for approval. Automated replenishment helps prevent overstocking costs and inventory loss due to theft or damage.

- Packaging

The environmental consequences of using packaging materials can be compounded when done incorrectly. Automated packaging and cartoning systems use precise algorithms to determine the best way to package materials with minimal waste.

- Shipping

Automated shipping systems are useful with the use of printers, size sensors, scales, conveyors, and software applications to select available carriers. They also estimate shipping costs and label packages for shipping.

What are the current trends in warehouse automation?

Here are the current automation trends that are starting to emerge in the warehousing industry around the world in an effort to keep up with technological advances and growing demand.

- Widespread use of robots

Robots will pay for themselves in about three to nine months; even small businesses with minimal budgets can invest in robots.

- AGV/AMR Mobile Robots

AGVs and Autonomous Mobile Robots (AMRs) are scalable and do not require two variations to the existing floor plan or warehouse infrastructure.

- Drones

Useful for efficient transportation, delivery, and scanning of barcodes and RFID tags, operating in hard-to-reach locations.

- Cobots

Cobots are specifically designed to work with humans. Currently, cobots account for less than 5% of the robot market and are expected to grow to 30.2% in the coming years.

Upgrade your automated warehouse system today!

Keeping up with today's competitive world requires an edge, and Intech Group is ready to help you gain that competitive edge to make your warehouse even more efficient! We have a wealth of experts ready to help you achieve that coveted perfect balance between warehouse supply and demand with innovative implementation strategies and cutting-edge automation technology. Contact us to learn more about how to implement an automated warehouse system into your business today! Hotline: 0966 966 032

Những câu hỏi thường gặp