Mini Conveyor Roller: Product Details

What is the difference between Mini Conveyor Rollers and other conventional conveyor rollers? You will find the answer with the information we provide to make the best choice.

The most essential part of the conveyor system is the type of conveyor rollers being used. During the assembly process, different types of materials are exploited such as metal, rubber or plastic, depending on their intended use in normal production operations. The use of rollers is necessary in combination with the nature of the environment and workplace in which it will be used. High-quality conveyor rollers are frequently applied in various industries, mainly manufacturing and warehouses due to their versatility in use. Rollers are designed and installed depending on the requirements of use, there are large sizes and smaller types. If you need a type, contact the supplier for the best advice and support. Here, we will help you learn about the Mini conveyor roller type that is commonly used for applications moving small, light loads in tight spaces.

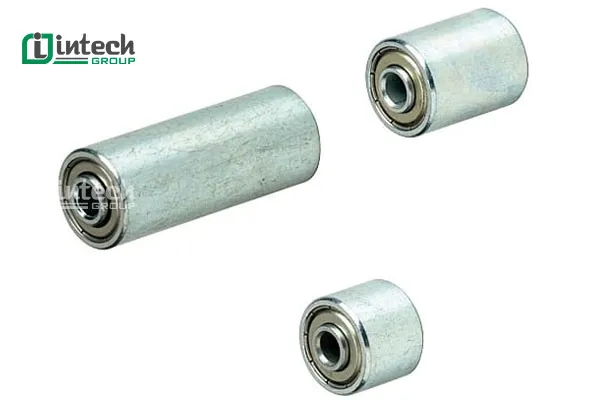

What is a mini conveyor roller?

Mini conveyor rollers are small rollers used in mini conveyor systems, used to support belts and transport goods. The structure of mini conveyor rollers mainly includes mandrels, tubes, bearings and sealing devices. Mini rollers are used like other common types. However, with their compact size, they are often used for the installation of small conveyor equipment to load small goods, making it easy to control products and the loading process.

Mini conveyor rollers are used in applications that require flexibility and space saving. Mini conveyor roller systems are adaptable and adjustable, and tend to be dismantled and moved efficiently without any problems.

Specifications of Mini Conveyor Roller:

- Diameter: φ89, φ102, φ108, φ114, φ127, φ133, φ139, φ152, φ159, φ165, φ194

- Length: L600

- Bearing: Single deep groove ball bearing

- Roller material is stainless steel, steel, plastic with high durability, beautiful, not bent, dented, deep scratched, rusted, moldy (appearance)

- Tensile strength 400-440MPa, plating thickness Z120.

- Shaft No warping, rust (appearance)

- Not exceeding the allowable tolerance (d0-0.05)

- Bearing shell, Lubricating oil, arc welding head is shielded with mixed gas

- The bearing shell and tube are fully welded to ensure good contact with the entire roller.

- Each roller will be strictly inspected and tested to ensure that every output is of truly high quality.

- Used in conveyors to transport small, light goods.

Things you need to know about Mini conveyor rollers

Mini rollers are miniature versions of the regular type, so they also have some similar characteristics. We will provide more insight into this product:

- How much does a mini conveyor roller weigh?

The weight of a mini roller can range from 300 grams to 900 grams, depending on the size, material, and also the specific design of each product. Typically, they are lighter in weight than their larger counterparts.

- What are mini conveyor rollers made of?

Like larger rollers, they are made from a variety of materials to meet specific conveying requirements. Choosing the material for your mini conveyor rollers should take into account your application, work environment, and budget. Here are some common materials:

- Steel: Typically used in applications that require high strength and good wear resistance. Steel can be plated or coated with corrosion protection to increase their life and performance

- Plastic: Mini conveyor rollers coated with plastic are typically used in light-duty applications or where a non-corrosive work environment is required.

- Stainless steel: In applications that require high corrosion resistance or strict hygiene requirements, rollers made from stainless steel are the optimal choice.

- What is the performance and life of mini conveyor rollers?

Designed and manufactured in the same way as their larger counterparts, their performance and service life are similar, lasting up to 5 or 7 years. However, Mini rollers need to comply with certain requirements to ensure durability and performance. For example, they are designed to be smaller to handle lighter weights and cannot be used for very heavy loads. Rollers made from stainless steel can better withstand corrosion in humid environments, while plastic types may be more suitable for chemically corrosive environments.

The design of mini conveyor rollers in conveyors is also important for performance and reliability. The design must consider factors such as the weight of the load, the speed of travel, and the working environment to ensure stable and efficient operation. In addition, the manufacturing process also affects the quality and reliability of the product. Using modern manufacturing technology and strict quality control procedures can help ensure that the final product meets high standards of performance and longevity.

- How much does it cost to produce mini conveyor rollers?

Certainly, the production cost for Mini conveyor rollers will be much lower than the large type of the same type due to less material and lower production costs. However, the cost also depends on the output quality of the product when using more modern production technology.

If you use light materials such as plastic or aluminum, you can reduce production costs compared to using steel or stainless steel. However, the material must also ensure sufficient quality to meet the requirements of durability and longevity.

Intech Group provides quality mini conveyor rollers at good prices

Nowhere else is Intech Group, we have everything you need in a high-quality Mini conveyor roller. We produce all kinds of rollers, conveyor rollers according to international standards, meeting the maximum needs of customers.

Why should you use Intech Group's Mini conveyor rollers?

- Experience and reputation: Intech Group has over 13 years of experience and reputation in the conveyor roller manufacturing industry, which can ensure that we have accumulated the necessary knowledge and skills to produce high quality and reliable products. Learn about Intech's popular conveyor rollers.

- Product quality: We have a team of experienced engineers, a standard quality management system, and strict product quality inspection before leaving the factory. This gives our customers peace of mind about the products, ensuring that they will receive products that meet high standards of performance and durability.

- After-sales service: Intech Group provides good customer support after sales, including maintenance, repair and 24/7 technical support

- Competitive price: Our roller products are competitively priced but still ensure product quality and performance.

Choosing Intech Group for mini roller products can ensure that you will receive high quality products, good support services, and competitive prices. This can help optimize the performance and reliability of your conveyor system.

Contact Intech Group now for the best quote:

- Hotline: 0966 966 032

- Address: Lot 6, Lai Xa Industrial Park, Tay Tuu Ward, Hanoi City

Những câu hỏi thường gặp