Industrial Conveyors

Conveyors are one of the most important and efficient processing systems used today in production lines and smart factories. Industrial conveyors serve production, assembly, sewing, processing, packaging, warehousing, etc. for many different purposes. Therefore, there will be many types of conveyors designed and manufactured to meet production requirements.

What is an industrial conveyor?

An industrial conveyor is a device, a loading and unloading system in factories, warehouses, logistics, distribution centers to transport raw materials and goods from location A to location B that has been calculated in advance. These locations can be the starting and ending points of the conveyor, or points in the conveyor's journey corresponding to the production stages.

In those small stages, raw materials and semi-finished products are taken out of the conveyor for processing, processing a certain stage and then returned to the conveyor to continue the journey. And so on until the end of the conveyor belt.

Products transported on the conveyor belt usually have the same fixed and similar journey. However, in current sorting lines, goods moving on the conveyor system with sorting equipment and technology will have different destinations depending on the purpose of the user.

Compared with other transportation methods, the conveyor system has many advantages such as higher capacity, lower cost, higher efficiency, less human involvement and high reliability.

-

![304 Stainless Steel Mesh Conveyor Belt]()

304 Stainless Steel Mesh Conveyor Belt

-

![90 degree curved plastic chain conveyor]()

90 degree curved plastic chain conveyor

-

![Free-Flow Conveyor System]()

Free-Flow Conveyor System

-

![Pallet chain conveyor]()

Pallet chain conveyor

-

![Cooling conveyor]()

Cooling conveyor

-

![White PVC conveyor belt]()

White PVC conveyor belt

-

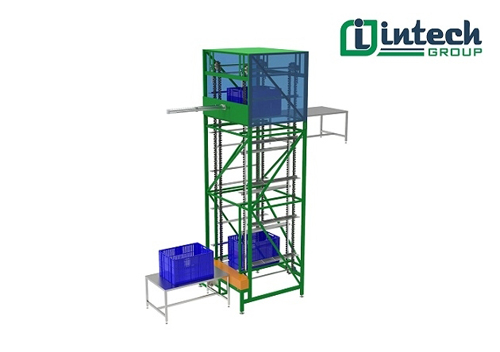

![Vertical Conveyor]()

Vertical Conveyor

-

![Pallet Conveyor]()

Pallet Conveyor

-

![180 degree curved conveyor belt]()

180 degree curved conveyor belt

-

![Curved Conveyor]()

Curved Conveyor

-

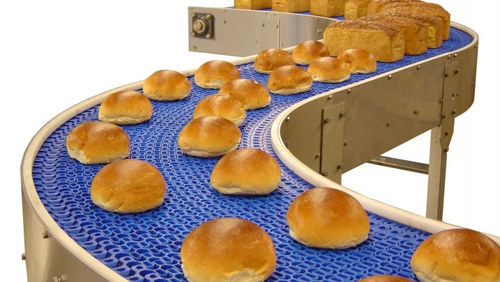

![Food Conveyor]()

Food Conveyor

-

![Rubber Conveyor Belts]()

Rubber Conveyor Belts

Những câu hỏi thường gặp