In industrial production environments that require high durability, strict hygiene (food, seafood) and heat resistance (drying ovens, ovens), traditional conveyor belts such as rubber or PVC often show many limitations. Therefore, the 304 Stainless Steel Mesh Conveyor Belt has emerged as an optimal alternative, being sought after by many.

What is a 304 Stainless Steel Mesh Conveyor Belt?

The 304 Stainless Steel Mesh Conveyor Belt is a type of conveyor belt that uses mesh made from 304 Stainless Steel interwoven together to transport goods and materials in many different industries, especially in environments with high temperatures, humidity or high hygiene requirements such as food and pharmaceutical processing. Its open mesh structure allows air, heat and moisture to circulate easily, while the 304 stainless steel material provides corrosion resistance, oxidation resistance, high durability and easy cleaning.

Detailed structure of 304 stainless steel mesh conveyor belt

A complete 304 stainless steel mesh conveyor belt system includes the following components:

- Conveyor frame (Frame): Acts as the load-bearing skeleton for the entire system. Usually made from 304 stainless steel, 201 stainless steel or powder-coated steel depending on environmental requirements and costs.

- Conveyor mesh: The 304 stainless steel mesh is where the product comes into contact and is transported, ensuring corrosion resistance, oxidation resistance, heat resistance and food hygiene and safety.

- Driven and passive pulleys/pulleys: These are rollers located at both ends of the conveyor belt. The driven pulley receives force from the motor and transmits motion to the conveyor mesh. The passive pulley is used to align and maintain the conveyor belt tension.

- Deceleration motor: Provides the force and speed required to operate the conveyor belt. The motor needs to be selected based on the load and speed requirements of the line.

- Control system: Includes inverter, switch, and control panel, allowing the operator to flexibly adjust the speed, direction of movement, and start/stop the conveyor belt.

- Tensioning part: Helps adjust the tension of the conveyor belt, avoiding the conveyor belt from sagging, skewing, or slipping during operation.

The synchronous combination of these parts, especially high-quality 304 stainless steel mesh, creates a powerful, hygienic, and extremely durable transport system.

Outstanding features of 304 Stainless Steel Conveyor Belt

304 Stainless Steel Conveyor Belt is a type of Austenitic stainless steel (containing at least 8% Nickel and 18% Chromium), providing the following advantages:

- Good corrosion resistance: Excellent rust and chemical corrosion resistance in humid environments, water, or exposure to mild chemicals. High temperature resistance: Can operate stably in high temperature environments (usually up to 300 degrees Celsius and can withstand oxidation temperatures up to 870 degrees Celsius).

- High durability and strength: 304 stainless steel mesh has good tensile strength and load bearing capacity.

- Easy cleaning: Smooth, non-stick surface, easy to clean with water or common cleaning chemicals.

- Open mesh structure: Allows air, heat, water/moisture to circulate and escape easily.

- Compare with other types of stainless steel conveyor mesh (201 and 316)

The main difference lies in the chemical composition, especially the Nickel (Ni) content, leading to differences in quality, corrosion resistance and price.

| Criteria | 201 Stainless Steel | 304 Stainless Steel | 316 Stainless Steel |

| Ni Content | Lowest (≈3.5%−5.5%) | Medium (≈8%−11%) | Highest (≈10%−14%) |

| Molybdenum (Mo) | None | None | Yes (≈2%−3%) |

| Corrosion Resistance | Worst, prone to rust in acid/salt environments | Good, most common | Best, superior |

| Hardness/wear resistance | Harder than 304 (due to high Manganese content) | Good mechanical hardness/wear resistance | Softer than 201, very good chemical resistance |

| Typical applications | Dry environments, low chemical content, low cost requirements | Food, pharmaceuticals, drying, general humid environments | Marine environments, strong chemicals, medical (where chlorine and strong acids are present) |

| Price | Cheapest | Reasonable (Mid-range) | Most Expensive |

Benefits of using 304 Stainless Steel Mesh Conveyor Belt

Here are the core benefits that make this product the top choice:

1. Ensure absolute hygiene

- Optimal corrosion resistance: With high Nickel content, 304 Stainless Steel is effective against rust and chemical corrosion in humid environments, salt water (aquatic products) or contact with mild acids/alkali in food.

- Easy cleaning: Smooth, non-stick surface prevents bacteria accumulation and is easy to clean with pressure spray or strong cleaning chemicals, meeting strict hygiene standards

2. Optimize heat treatment and drying processes

- High heat resistance: The conveyor belt operates durably in high temperature environments (drying ovens, ovens) without deformation or oxidation.

- Absolute ventilation: The open mesh structure allows air, heat and moisture to circulate through the product easily. This helps the drying, baking or cooling process to take place quickly and evenly, thereby saving energy and shortening production time.

3. Economical performance and durability

- Outstanding durability: Stainless steel 304 has good mechanical strength and load capacity, ensuring a long service life, reducing the frequency of replacement and maintenance costs.

- Flexible operation: Suitable for many harsh working conditions (hot, cold, humid) and can be designed with many different knitting patterns to suit each type of product.

- Anti-stick: Especially effective in the freezing industry, 304 stainless steel helps prevent products (such as seafood) from sticking to the mesh, ensuring productivity.

Practical applications of 304 stainless steel mesh conveyor belts in industries

The ability to resist heat, corrosion and ensure hygiene has made 304 stainless steel mesh conveyor belts an irreplaceable solution in many key industries.

- Food and Beverage Processing Industry

This is the most common and important application field due to the requirements for food hygiene and safety and heat treatment ability.

- Drying and baking: Transporting confectionery, cereals, seeds, agricultural products through drying ovens and ovens. Open mesh helps heat circulate evenly, optimizing drying and cooking efficiency.

- Refrigeration and freezing: Transfer products (seafood, vegetables and fruits) through freezing chambers. 304 stainless steel is non-stick at low temperatures and can withstand humid, cold environments.

- Washing and blanching: Transport vegetables, fruits, or seafood through sinks, steam blanching. The mesh structure helps drain water quickly and effectively remove impurities.

- Pharmaceutical and medical industry

304 stainless steel mesh conveyor belts are used in processes that require a sterile and easy-to-clean environment.

- Sterilization and drying: Transport blister packs, medical instruments or pharmaceutical ingredients through sterilization or heat drying machines.

- Primary packaging: Ensure a clean, anti-bacterial transport surface for products in direct contact.

- Seafood industry

The characteristics of this industry are high humidity environments, frequent contact with salt water or water with changing pH.

- Processing and sorting: Transporting shrimp, fish, squid through washing, sorting and draining stages.

- Anti-salt corrosion: The excellent rust resistance of 304 stainless steel is ideal for resisting corrosion from seawater and salt.

- Other industries

- Electronic components manufacturing: Drying or heat treating circuit boards, small components.

- Chemical and textile: Transporting materials through areas that need to be dried or exposed to mild chemicals (sorting, drying dyes, chemicals).

- Metallurgy: Used in some applications for cooling or high temperature treatment of small parts.

Experience in using 304 stainless steel mesh conveyor belt

The practical experiences below will help you have a deeper insight into the selection and operation of 304 stainless steel mesh conveyor belt.

1. Experience in choosing the optimal 304 stainless steel mesh conveyor belt

- Accurately determine the mesh material:

- 304 stainless steel is the standard: Always request a material certificate (CO/CQ) to verify that the mesh is standard 304 stainless steel, not cheap 201 stainless steel. 201 stainless steel will rust quickly in humid environments or in contact with chemicals.

- Consider 316 for harsh environments: If the conveyor belt operates in seawater (seafood processing) or is exposed to strong acids, invest in 316 stainless steel despite the higher cost, because 304 can still suffer from pitting corrosion in concentrated chloride environments.

- Select the weaving style and mesh pitch:

- Product size: Choose a mesh pitch (square size) smaller than the smallest item you are transporting to avoid the product from slipping or getting stuck.

- If maximum drying/drainage is required, choose a mesh with high clearance (large mesh).

- If transporting thin, easily deformed products, choose a tight weave, creating a flatter surface to increase contact area and support.

- Drive system design:

- Use Edge Chains: For long or heavy-duty conveyor belts, choose a design with load-bearing chains (chains) on both sides of the mesh. The chain helps transmit force accurately, preventing the mesh from slipping or shifting when carrying heavy loads, especially when changing direction.

- Drive pulley: The pulley must be designed as a gear to mesh precisely with the mesh or edge chain, ensuring the mesh does not slip when starting or accelerating.

2. Operation and maintenance experience

- Mesh tension:

- Do not over-tighten: Metal mesh conveyor belts, especially when hot, are prone to expansion. Over-tightening the mesh will increase the load on the motor and cause rapid wear at the joints (rods and yarns).

- Periodic inspection: Regularly check the tension of the mesh when the conveyor belt is at both normal operating temperatures and high temperatures (if heated).

- Cleaning and maintenance:

- Regular cleaning: Take advantage of the easy-to-clean properties of Inox 304. After each shift, wash with a pressure spray and cleaning chemicals (suitable for Inox) to remove grease, food residue, prevent bacterial accumulation and local rust.

- Check the lubricating grease: Ensure moving parts such as bearings and shafts are properly lubricated. Use heat-resistant grease if the conveyor belt is operating in a high temperature environment.

- Troubleshooting common problems:

- Net misalignment: This is a common problem. Usually due to improper installation, uneven tensioning of the net, or unbalanced load distribution. The net tensioner at the driven end needs to be readjusted until the net runs straight on the shaft.

- Check for damaged mesh: If some of the knitting wires or crossbars are broken/broken, they need to be replaced or repaired locally immediately to avoid damaging the entire mesh due to the spreading problem.

How much is the price of 304 stainless steel mesh conveyor belt?

The price of 304 stainless steel mesh conveyor belt does not have a fixed level but depends entirely on the design and technical requirements of each project.

- Reference price:

- Simple: About 30 million VND or more.

- Standard (Food, drying): Common from 50 million to 200 million VND.

- Complex (Large capacity, curved, high heat resistance): From 200 million VND or more.

- Factors that determine the price of the conveyor belt:

- Mesh size: Length and width of the conveyor mesh, thickness of the stainless steel wire and knitting density (thick, tightly woven wires will be more expensive).

- Drive design: Frame material (304/316 stainless steel or steel).

- Power and electrical equipment: Motor/Gearbox capacity and use of Inverter from reputable brands.

- Tips: To get an accurate quote, you need to provide full parameters such as maximum load, length, width, and operating environment to the supplier.

Reputable address to buy 304 stainless steel mesh conveyor

304 stainless steel mesh conveyor is the optimal solution, bringing economic efficiency and outstanding durability to industries that require the strictest standards of hygiene and temperature. Choosing 304 stainless steel is choosing stability, safety and long life for your production line.

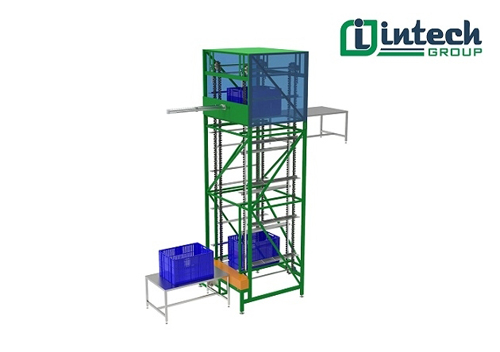

You can buy 304 stainless steel mesh conveyor at Intech Group - one of the leading units in Vietnam supplying this product line. Intech Group specializes in providing solutions for conveyors, automation systems, and industrial equipment. 304 Stainless Steel Mesh Conveyor Belt is one of our main products, designed and manufactured according to the specific requirements of each industry.

Reasons to choose Intech Group:

- Proactive production: Design and manufacture complete packages (from A-Z), ensuring perfect customized conveyor belts according to your process.

- Quality assurance: Commitment to standard 304 Stainless Steel Mesh

- Extensive experience: Reputable unit, specializing in providing solutions for the food and pharmaceutical industries

- Complete service: Support from survey, installation to clear warranty and maintenance.

To receive in-depth advice on design and quotation of 304 stainless steel mesh conveyor belt, you should contact Intech Group directly:

Contact information:

- Hotline: 0966 966 032

- Email: info@intech-group.vn

- Address: Lot 6, Lai Xa Industrial Cluster, Tay Tuu Ward, Hanoi City

Những câu hỏi thường gặp

❖

Sản phẩm cùng loại khác