Conveyor - Conveyor Systems

Conveyor belts are present as an indispensable companion in industrial production and daily life. This is a mechanical device that takes on the role of transporting goods over all distances. They are truly the optimal solution for transporting goods, bringing convenience and safety to users.

Conveyor belts are mechanical devices used to transport materials and goods from one location to another. Conveyors have a simple structure but are highly efficient and are widely used in many different fields. Conveyors are durable and reliable transport equipment used in automated distribution and warehousing, as well as manufacturing plants.

This is considered a labor-saving system, allowing large volumes of materials to move quickly in the process, helping companies transport or receive goods in larger volumes in smaller storage spaces and with lower labor costs. (According to wiki)

Here are some typical applications of conveyor systems

Intech conveyor helps transport materials in industry, warehouses, logistics quickly, easily, safely and at optimal cost savings.

Intech Group is proud to have provided standard conveyors and automation solutions, providing advanced industry for many years. Applying modern technology allows Intech Group to provide the best solutions for automation and material handling requirements. To improve operational efficiency and increase production capacity of Customers. Maximum flexibility, excellent quality and easy integration make Intech conveyors the top choice in Vietnam.

Conveyor prices depend on many factors, including conveyor type, size, material, capacity, and customized requirements. Intech Group offers many types of conveyors such as roller conveyors, PVC conveyors, chain conveyors, mesh conveyors, drying conveyors, etc. Each type will have a different price. Please provide detailed information about your usage needs for the most accurate advice and quote.

Contact Intech Group:

What is a conveyor belt?

Conveyor belts are mechanical devices used to transport materials and goods from one location to another. Conveyors have a simple structure but are highly efficient and are widely used in many different fields. Conveyors are durable and reliable transport equipment used in automated distribution and warehousing, as well as manufacturing plants.

This is considered a labor-saving system, allowing large volumes of materials to move quickly in the process, helping companies transport or receive goods in larger volumes in smaller storage spaces and with lower labor costs. (According to wiki)

Basic structure of the conveyor belt:

- Conveyor frame system: Used to support and keep the conveyor belt stable when moving goods. The frame must ensure firmness, good load-bearing capacity, high durability, and withstand impacts from the surrounding environment. It is often made of stainless steel, aluminum profiles, galvanized steel, and powder-coated steel.

- Conveyor belt: Used to move and transport goods from one location to another. Usually uses PVC belts with optional thicknesses of 2mm, 3mm, 5mm or PU belts with thicknesses of 1.5mm, 2mm. There are blue, white, gray, or ribbed belts. In addition, the conveyor belt also uses stainless steel mesh, stainless steel chains, and plastic chains for special applications with high durability and resistance to impacts from the working environment.

- Conveyor height: from 800mm to 1100mm

- Conveyor length: 1000, 1500, 2000, 2500, 3000, 4000, 5000mm. 100, 150,200, 300, 400, 500, 600mm.

- Belt width: 40mm, 80mm, 100mm, 200mm, 300mm, 400mm, 600mm

- Roller size: diameter 25.4, 35, 50mm.

- Supporting and transmitting part: The traction roller and support roller use galvanized steel, stainless steel or aluminum rollers. Size Ø50, Ø60, Ø76, Ø89, Ø102, Ø114, Ø133, Ø168 ...

- Rollers: active roller, passive roller, belt support roller, flat pressing roller. Rollers are made of steel, stainless steel with standard diameter.

- Standard speed for most unit processing conveyors is: 34cm/s

- Speed controller: Inverter, sensor, timer, sensor, PLC ...

- The motor is designed to move in both directions and is located in the middle, end or beginning of the system. There are systems driven by belts or chains. Liquids, granular and powder materials can have a conveying system using pneumatic power or screw drive.

- Accessories: bolts, screws, bearings, adjustable feet, wheels...

- The conveyor system must meet safety requirements and comply with regulations when used.

Applications of conveyor systems in industry

| |

Here are some typical applications of conveyor systems

- In the electronics manufacturing industry, conveyors are used to transport small, light electronic components between production stages accurately and safely.

- In the automobile manufacturing industry, conveyors are used to transport heavy vehicle parts on the automobile assembly line effectively.

- Conveyors easily transport raw materials and finished products in food processing plants, ensuring food hygiene and safety.

- Some other industries such as pharmaceuticals, beverages, garments, etc. also commonly use conveyors to transport a variety of materials over certain distances.

- The conveyor system helps automate the transportation of goods from warehouses to trucks and containers, saving time and labor. Supports the scientific arrangement and storage of goods in the warehouse, optimizing storage space.

- The conveyor helps increase the speed of loading and unloading goods at seaports and airports, contributing to shortening transportation time. Helps connect different means of transport such as ships, airplanes, and trucks effectively.

- The conveyor helps automatically transport goods from the receiving area to the display area, saving labor and improving service quality. Brings a modern and professional shopping experience to customers.

- The conveyor is used to transport rice, corn, potatoes, fruits, vegetables and other agricultural products in the processing area quickly and efficiently. Helps minimize loss of agricultural products during transportation and storage.

- Heavy-duty conveyor to transport sand, stone, cement from trucks to construction sites quickly and safely. Contribute to improving construction productivity and shortening construction time.

Why should you choose Intech Group conveyors to deliver goods?

Intech conveyor helps transport materials in industry, warehouses, logistics quickly, easily, safely and at optimal cost savings.

- Innovative design, high quality products

- High durability, reliable operation

- The most competitive conveyor belt price

- Professional service, dedicated support

- With many customized solutions

Intech Group is proud to have provided standard conveyors and automation solutions, providing advanced industry for many years. Applying modern technology allows Intech Group to provide the best solutions for automation and material handling requirements. To improve operational efficiency and increase production capacity of Customers. Maximum flexibility, excellent quality and easy integration make Intech conveyors the top choice in Vietnam.

Intech conveyor price quote:

Conveyor prices depend on many factors, including conveyor type, size, material, capacity, and customized requirements. Intech Group offers many types of conveyors such as roller conveyors, PVC conveyors, chain conveyors, mesh conveyors, drying conveyors, etc. Each type will have a different price. Please provide detailed information about your usage needs for the most accurate advice and quote.

Contact Intech Group:

- Address: Lot 6, Lai Xa Industrial Park, Tay Tuu Ward, Hanoi City

- Hotline/Zalo: 024 66 806 795 - 0966 966 032

- Email: info@intech-group.vn

-

![304 Stainless Steel Mesh Conveyor Belt]()

304 Stainless Steel Mesh Conveyor Belt

-

![90 degree curved plastic chain conveyor]()

90 degree curved plastic chain conveyor

-

![Free-Flow Conveyor System]()

Free-Flow Conveyor System

-

![Roller conveyor carrying pallets containing car tires]()

Roller conveyor carrying pallets containing car tires

-

![Pallet chain conveyor]()

Pallet chain conveyor

-

![Roller Conveyor Combined with AGV Robot]()

Roller Conveyor Combined with AGV Robot

-

![Pallet transport roller conveyor]()

Pallet transport roller conveyor

-

![Cooling conveyor]()

Cooling conveyor

-

![White PVC conveyor belt]()

White PVC conveyor belt

-

![Water purifier assembly line]()

Water purifier assembly line

-

![Pallet transport conveyor]()

Pallet transport conveyor

-

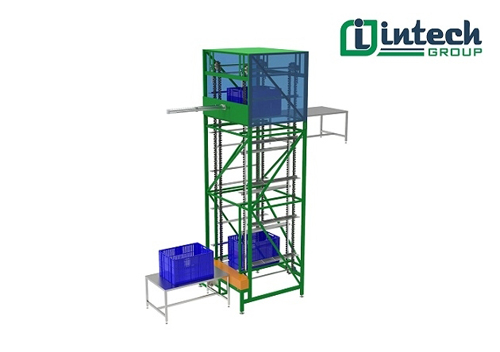

![Vertical Conveyor]()

Vertical Conveyor

Những câu hỏi thường gặp

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)