The free-flow conveyor system is a modern automation solution that helps improve efficiency and productivity in assembly lines. Unlike traditional conveyors, this system allows product trays (called jigs) to move independently, providing maximum flexibility for the production process.

The free-flow conveyor system is designed with the following main components:

![freeflow conveyor system freeflow conveyor system]()

Free-flow conveyor systems bring many practical benefits, contributing to significantly improving production efficiency:

![freeflow conveyor system freeflow conveyor system]()

Intech Group is proud to be a trusted partner, providing efficient and quality conveyor solutions for businesses. We have just completed and successfully delivered a 25-meter long freeflow conveyor system to a Canadian factory in Vietnam, a clear demonstration of our capacity and reputation.

At Intech Group, conveyors are not just a product, they are also our commitment to superior quality. We always ensure:

We are always ready to accompany domestic and foreign businesses to improve productivity and automate production processes.

For detailed advice and quotation, please contact:

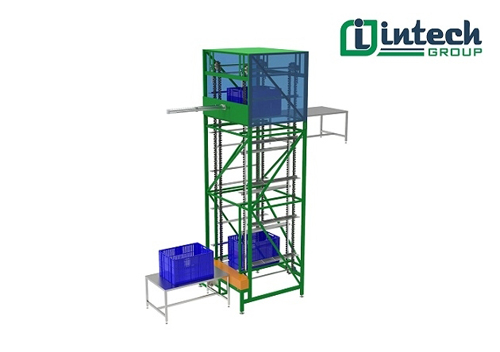

Main structural features of the freeflow conveyor system for transporting Jigs

The free-flow conveyor system is designed with the following main components:

- Free-flow chain conveyor: This is the core part, responsible for transporting jigs containing products. The outstanding feature of this type of conveyor is the ability to allow each jig to stop at a work station without affecting the movement of other jigs on the line.

- Control button at each station: Each work station is equipped with a control button. Workers only need to press this button after completing the job, the jig will automatically move to the next station. This helps to actively control the production speed.

- Lighting and upper shelves: Support assembly workers in good lighting conditions, can attach additional tools/components.

- Jig return cluster: At the end of the line, when the product is completed and taken out, the jig will be returned to the beginning of the line by the conveyor belt below.

Operating principle of the freeflow conveyor system

- Jig enters station 1 → workers assemble or inspect.

- When finished, the worker presses the control button → the conveyor pushes the jig to the next station.

- The process repeats until the last station, where the finished product is taken out.

- The jig, after being empty, will be returned to the first station by the return line system, ready for a new loop.

Advantages of freeflow conveyor systems:

Free-flow conveyor systems bring many practical benefits, contributing to significantly improving production efficiency:

- Saving manpower: Workers do not have to move much to pick up or move products, the jig automatically runs between stations.

- Progress control: The jig only runs when the worker finishes operating, avoiding motor failure due to the conveyor belt operating continuously during the production process (the motor does not have to run - stop continuously, which can easily damage the motor in the long run). This helps to better control the speed and prolong the life of the equipment

- Increase productivity: Multiple workers can be arranged on the same line, each person taking on a stage. This specialization helps to increase the overall speed and output of the line.

- Circulation: The jig always returns to the starting point, no need to add a new tray.

Intech Group: Elevating production with advanced conveyor solutions

Intech Group is proud to be a trusted partner, providing efficient and quality conveyor solutions for businesses. We have just completed and successfully delivered a 25-meter long freeflow conveyor system to a Canadian factory in Vietnam, a clear demonstration of our capacity and reputation.

At Intech Group, conveyors are not just a product, they are also our commitment to superior quality. We always ensure:

- Top quality: Products meet the most stringent technical standards.

- Optimizing costs: Providing solutions at reasonable prices, helping businesses optimize investment efficiency.

- Specialized solutions: Designing and manufacturing systems suitable for the characteristics of each manufacturing industry.

We are always ready to accompany domestic and foreign businesses to improve productivity and automate production processes.

For detailed advice and quotation, please contact:

- Hotline: 0966.966.032 - 0983.113.387

- Factory address: Lot 6, Lai Xa Industrial Cluster, Tay Tuu Ward, Hanoi City

- E-mail: info@intech-group.vn

Những câu hỏi thường gặp

❖

Sản phẩm cùng loại khác