A cooling conveyor is a conveyor system specially designed to cool products during production or processing. This system is often used in industries where products need to be cooled quickly after being heated, such as:

The accuracy and efficiency of the conveyor during the casting cooling process plays an important role in maintaining product quality standards. If the product is not cooled properly, it can lead to deformation or reduced durability of the casting product. Therefore, using a casting cooling conveyor helps ensure that the product will achieve the best quality and comply with production standards.

With many years of experience in the machinery assembly and processing industry, Intech Group is committed to bringing customers the most quality and reputable solutions. The casting cooling conveyor system is designed and installed according to the specific requirements of each enterprise, ensuring the highest operating efficiency and cost savings.

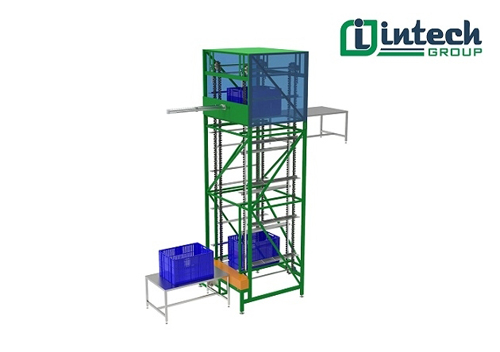

Image of Intech Group installing a conveyor to cool cast products

![Cooling conveyor Cooling conveyor]()

![Cooling conveyor Cooling conveyor]()

Contact to purchase

For more information about the service of installing a conveyor to cool cast products, you can contact Intech Group:

- Food industry: Cooling food after cooking, baking or frying.

- Metal manufacturing industry: Cooling metal products after heat treatment.

- Plastics industry: Cooling plastic products after molding or pressing.

Main features of cooling conveyor:

- Cooling system: The conveyor is equipped with a cooling system, which can use fans, water or cold air to reduce the temperature of the product.

- Heat-resistant materials: The conveyor is usually made of heat-resistant materials such as stainless steel, heat-resistant plastic or heat-resistant rubber.

- Optimized design: The conveyor is designed to optimize the cooling process, ensuring that the product is cooled evenly and quickly.

Intech Group installs a casting cooling conveyor according to customer requirements

The accuracy and efficiency of the conveyor during the casting cooling process plays an important role in maintaining product quality standards. If the product is not cooled properly, it can lead to deformation or reduced durability of the casting product. Therefore, using a casting cooling conveyor helps ensure that the product will achieve the best quality and comply with production standards.

With many years of experience in the machinery assembly and processing industry, Intech Group is committed to bringing customers the most quality and reputable solutions. The casting cooling conveyor system is designed and installed according to the specific requirements of each enterprise, ensuring the highest operating efficiency and cost savings.

Product specifications:

- Size: L4000xW400xH2000mm

- Using high-strength stainless steel conveyor belt

- The heater ensures a temperature of 50 - 250 degrees °C

- Speed up to 15m/min

- Load capacity up to 50kg/m

- Electrical cabinet, conveyor motor T040W

- Bearings: Quantity is 2

- Cooling fan: Quantity is 5

- Wheels: Quantity is 6

- Bearings: Quantity is 2

- Passive gear: SP50B18-N-28

- Active gear: SP50B16-N-32

- Drive chain set

- Stainless steel plate chain conveyor moves the product

Image of Intech Group installing a conveyor to cool cast products

Contact to purchase

For more information about the service of installing a conveyor to cool cast products, you can contact Intech Group:

- Hotline: 0966 966 032

- Email: info@intech-group.vn

- Address: Lot 6, Lai Xa Industrial Park, Tay Tuu Ward, Hanoi City

Những câu hỏi thường gặp

❖

Sản phẩm cùng loại khác