For the food processing industry, the requirements of food safety and hygiene are always a top priority. Therefore, the production process is always strictly controlled, the food handling system must be kept clean. Conveyor equipment used for the food industry plays the role of transporting, serving the processing and packaging process. Food conveyors move food and other organic materials through their processes safely and quickly.

Food conveyors are mechanical systems designed to efficiently transport raw materials and finished products through the stages of production and processing along a production or packaging line. Food conveyors must meet strict hygiene and safety standards because they directly affect food safety. Conveyors are often made of materials such as stainless steel to make them easy to clean and to withstand varying temperatures and conditions.

Depending on the process, these conveyors can also be equipped with features to sort, cool, or heat the products they handle. These systems are essential to modern food manufacturing, allowing for consistent, high-volume production and packaging.

![Băng tải thực phẩm Băng tải thực phẩm]()

Food industry conveyors are designed to be easy to clean and move food ingredients safely and efficiently. This is important to ensure that food hygiene and safety standards are met, with no chance of cross-contamination.

The most common types of belt conveyors in the food industry. Because their texture gives a smooth surface, and they are very easy to clean. Belt materials for food-based applications must meet food safety regulations. It must also be strong, durable and made of acceptable use materials. It is important that materials authorized for use with food products are easily cleaned at all times.

Plastic conveyor belts used for the food industry often use PP plastic belts to ensure food safety requirements. PVC conveyor belts can be selected for packaging food conveying requirements. Modular plastic link belt type when durability and cold temperatures are required.

* Advantages of plastic conveyor belts for the food industry![Băng tải đai nhựa chế biến củ quả Băng tải đai nhựa chế biến củ quả]()

Food drying conveyor is used to dry foods such as agricultural products, vegetables, seafood... Conveyor is designed to be simple, easy to use, can adjust the drying temperature for each type. product. The conveyor surface is easy to clean, does not stick to food and limits bacteria from sticking to the conveyor surface. In particular, the food drying conveyor has good heat resistance, so it can be used in the drying and packaging process.

* Structure of food drying conveyor:

Food chain conveyors are commonly used in the production of beverages, soft drinks, beer, wine, sandwiches... Chain conveyors are linked by longitudinal chains. With the advantage of reducing noise, high durability, and low cost, food chain conveyor is the best choice for moving goods.

![Băng tải xích nhựa cho nước đóng chai và đồ uống Băng tải xích nhựa cho nước đóng chai và đồ uống]()

Food grade wire mesh conveyor belt is made of stainless steel material. Can withstand high and low temperatures, and products are less likely to stick to them. Wire mesh belt conveyors are available in any length, width or speed to suit the specific requirements of the application.

![Băng tải lưới thép cho quy trình nướng bánh mì Băng tải lưới thép cho quy trình nướng bánh mì]()

These include centrifugal rollers, chain-driven direct rollers, shaft-driven direct rollers, and mechanically driven rollers. These conveyors are custom built to suit the application tools. That can include washdown environments, specific temperature ranges, and more. With simple yet effective configurations, roller conveyors play an important role in the work of moving raw materials and products through the production stages, from pre-processing to packaging.

Roller conveyors are used in product chains, frozen foods, beverages, etc.

![Băng tải con lăn trong chế biến củ quả Băng tải con lăn trong chế biến củ quả]()

To ensure safety, efficiency and prolong the life of food conveyors, users need to note the following points:

Maintaining hygienic conditions requires not only the initial design and installation of the food conveyor, but also regular cleaning and maintenance. This involves conducting regular inspections to identify potential problem areas that may need repair. It also requires establishing and following scheduled cleaning procedures to remove any debris or bacteria build-up, including thorough cleaning of the conveyor surface and especially crevices and seams where food particles can collect.

To keep the conveyor free of harmful bacteria, it is important to clean it properly with food-grade cleaning and sanitizing solutions, and always follow the specified instructions for use. Lubricating moving parts with food-grade lubricants, as recommended by the manufacturer, is essential to ensure the conveyor runs smoothly and efficiently. It is equally important to document all cleaning and maintenance activities so that there is a detailed record of the procedures performed, when they were performed, and any issues identified and corrected during these procedures.

Conveyors play an important role in many food processing and manufacturing industries, bringing great efficiency and benefits to businesses. Some specific applications help you better understand this equipment:

Food conveyor belts are important and versatile equipment, bringing many benefits to businesses in many different industries. Choosing the right conveyor belt will help businesses optimize the production process, improve efficiency and product quality, while saving costs and ensuring labor safety.

When choosing a food conveyor for your business, there are several important aspects to consider to ensure that it meets your specific needs and requirements.

- Hygiene and Cleanliness

The conveyor should be designed with materials and construction that can withstand regular cleaning and sanitizing. Stainless steel is a popular choice because of its durability and resistance to corrosion. Sealed bearings and other components should be used to minimize the possibility of bacteria buildup. Additionally, it is important to consider how easy it is to clean and sanitize the conveyor.

- Capacity and Efficiency

The conveyor should be able to handle the volume and weight of material that your business requires. Speed and incline should also be considered to ensure that the conveyor can move the product efficiently. Additionally, it is important to consider the capacity of the conveyor and how it will affect your overall production process. Think about how many products you need to transport per hour and how it will fit into your production process. Also, consider variations in the size, shape, and weight of the products being transported, as well as future expansion and scalability when selecting a conveyor.

- Durability and maintainability

The conveyor should be made of durable materials and construction to minimize the need for frequent repairs and maintenance. Stainless steel is also a popular choice here because of its durability and corrosion resistance. It should also be designed with accessibility in mind for easy cleaning and maintenance. This includes features such as removable belts and easily accessible parts for cleaning and maintenance.

- Customization and Integration

Your future conveyor should be customized to meet your specific needs and floor space requirements. Custom conveyor systems are a good option for facilities that cannot accommodate standard conveyor sizes or layouts. They include specialized modules that you can add or remove depending on the needs of your production process.

A new conveyor should integrate seamlessly with other equipment in your facility, such as packaging machines, to create an automated conveyor system. There is no point in investing in a new conveyor only to find out that the equipment you already have on your production line cannot work with it. Additional options, such as adding sensors or integrating with control systems, are also welcome on new conveyors.

- Safety and Ergonomics

Safety should be a top priority when selecting a food conveyor. It should comply with industry regulations and have features such as guardrails and emergency stop buttons to protect the operator and other workers from potential hazards such as pinch points and to minimize the risk of injury in the event of an emergency. Additionally, the conveyor should be designed with operator ergonomics in mind, such as height adjustment and easy-to-use controls, to minimize the risk of injury and fatigue while allowing for more comfortable and efficient operation.

- Consider Your Budget

When choosing a food conveyor, it is important to consider the total cost of ownership, which includes the initial cost of the conveyor, installation costs, and ongoing maintenance costs.

Return on investment (ROI) is a way to measure the financial performance of an investment, in this case a conveyor. It is calculated by taking the net benefit of the investment (cost savings or increased revenue) and dividing it by the total cost of the investment (initial cost, installation cost, and ongoing maintenance cost). A higher ROI means the investment is more profitable. By considering the long-term costs and potential ROI, you can make a more informed decision about whether a conveyor is a good investment for your business.

Food conveyors play a vital role in ensuring food safety and production efficiency. Therefore, these equipment must comply with strict standards and regulations. Main standards and regulations

- Material standards:

- Design standards:

- International and Vietnamese standards

Intech Company is proud to be the leading reputable food conveyor manufacturer in Vietnam, with many years of experience in the field of design, manufacture and installation of conveyor systems for the food processing industry. We provide a variety of food conveyors to suit all customer needs. Intech's food conveyor products are made from high-quality materials, ensuring food safety and hygiene and high durability. We apply advanced technology in production, combined with a team of highly skilled engineers, to bring customers the best quality products at competitive prices.

Intech also provides consulting, design and installation services for complete conveyor systems, meeting all customer requirements. We are committed to bringing customers absolute satisfaction with product quality and service.

Contact Intech today for free consultation and detailed quotes on food conveyor products!

Contact information:

What is a food conveyor?

Food conveyors are mechanical systems designed to efficiently transport raw materials and finished products through the stages of production and processing along a production or packaging line. Food conveyors must meet strict hygiene and safety standards because they directly affect food safety. Conveyors are often made of materials such as stainless steel to make them easy to clean and to withstand varying temperatures and conditions.

Depending on the process, these conveyors can also be equipped with features to sort, cool, or heat the products they handle. These systems are essential to modern food manufacturing, allowing for consistent, high-volume production and packaging.

Structure of conveyor food:

- Conveyor frame is designed with stainless steel, galvanized steel, profiled aluminum, ..

- Conveyor belt: PU, PVC, or use modular bonding plastic

- Conveyor belt width: 300 - 600mm.

- Conveyor length: 3 - 8m

- Number of floors of conveyor according to customer requirements.

- Geared motor: 380v, 3phase, 50hz…

- Controller: inverter, switch,..

Advantages of using food industry conveyors

Food industry conveyors are designed to be easy to clean and move food ingredients safely and efficiently. This is important to ensure that food hygiene and safety standards are met, with no chance of cross-contamination.

- Food conveyors are designed to be sturdy and can operate for many hours.

- The conveyor surface has good anti-stick properties and helps ensure food hygiene and safety.

- The conveyor frame is rust-proof and abrasion-resistant, allowing the conveyor to have a long service life.

- It does not make much noise when operating.

- Consumes little electricity when operating, and the conveyor is easy to clean when not in use.

- Using food conveyors helps shorten production time and improve work efficiency.

Types of conveyor belts for the food industry commonly used today:

The most common types of belt conveyors in the food industry. Because their texture gives a smooth surface, and they are very easy to clean. Belt materials for food-based applications must meet food safety regulations. It must also be strong, durable and made of acceptable use materials. It is important that materials authorized for use with food products are easily cleaned at all times.

1 - Food grade plastic conveyor belt

Plastic conveyor belts used for the food industry often use PP plastic belts to ensure food safety requirements. PVC conveyor belts can be selected for packaging food conveying requirements. Modular plastic link belt type when durability and cold temperatures are required.

* Advantages of plastic conveyor belts for the food industry

- Plastic straps are cheap, easy to assemble and maintain

- Modular plastic belt style provides maximum hygiene, high resistance to corrosion and wear

- Stable operation, low noise

- No sharp edges endangering personnel or moving product

2 - Food drying conveyor

Food drying conveyor is used to dry foods such as agricultural products, vegetables, seafood... Conveyor is designed to be simple, easy to use, can adjust the drying temperature for each type. product. The conveyor surface is easy to clean, does not stick to food and limits bacteria from sticking to the conveyor surface. In particular, the food drying conveyor has good heat resistance, so it can be used in the drying and packaging process.

* Structure of food drying conveyor:

- Dimensions: W630xL6000

- Frame in NDH 40x80

- 180W geared motor, Control cabinet

- Insulated drying chamber

- 6 fans/drying chamber

- Drying ball 1.2m, 3 balls/ Drying chamber

- PVC Belt t=3mm

- The temperature is 80 degrees C

- Conveyor helps to evenly dry all sides of the material

- Can be heated midway, control air flow easily

- High drying efficiency, saving electricity in the production process

- Easy to use, install, operate and maintain

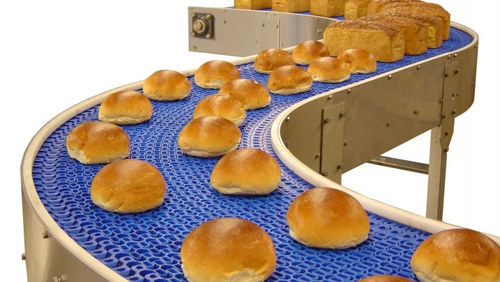

3 - Food chain conveyor

Food chain conveyors are commonly used in the production of beverages, soft drinks, beer, wine, sandwiches... Chain conveyors are linked by longitudinal chains. With the advantage of reducing noise, high durability, and low cost, food chain conveyor is the best choice for moving goods.

4 - Wire Mesh Conveyor

Food grade wire mesh conveyor belt is made of stainless steel material. Can withstand high and low temperatures, and products are less likely to stick to them. Wire mesh belt conveyors are available in any length, width or speed to suit the specific requirements of the application.

6 - Roller Conveyor

These include centrifugal rollers, chain-driven direct rollers, shaft-driven direct rollers, and mechanically driven rollers. These conveyors are custom built to suit the application tools. That can include washdown environments, specific temperature ranges, and more. With simple yet effective configurations, roller conveyors play an important role in the work of moving raw materials and products through the production stages, from pre-processing to packaging.

Roller conveyors are used in product chains, frozen foods, beverages, etc.

Some important notes on using food conveyors:

To ensure safety, efficiency and prolong the life of food conveyors, users need to note the following points:

- Install the conveyor according to the manufacturer's instructions, carefully check the electrical system before operating

- Do not overload, Do not let foreign objects or sharp objects fall on the conveyor.

- Use the correct transport speed appropriate to the type of product and usage needs.

- Clean the conveyor regularly after each use to ensure food hygiene and safety.

- Turn off the power when not using the conveyor.

Regular cleaning and maintenance requirements for food conveyors

Maintaining hygienic conditions requires not only the initial design and installation of the food conveyor, but also regular cleaning and maintenance. This involves conducting regular inspections to identify potential problem areas that may need repair. It also requires establishing and following scheduled cleaning procedures to remove any debris or bacteria build-up, including thorough cleaning of the conveyor surface and especially crevices and seams where food particles can collect.

To keep the conveyor free of harmful bacteria, it is important to clean it properly with food-grade cleaning and sanitizing solutions, and always follow the specified instructions for use. Lubricating moving parts with food-grade lubricants, as recommended by the manufacturer, is essential to ensure the conveyor runs smoothly and efficiently. It is equally important to document all cleaning and maintenance activities so that there is a detailed record of the procedures performed, when they were performed, and any issues identified and corrected during these procedures.

Applications of food conveyors

Conveyors play an important role in many food processing and manufacturing industries, bringing great efficiency and benefits to businesses. Some specific applications help you better understand this equipment:

- Conveyors transport raw materials from the receiving area to the warehouse or to the production line. Application of food conveyor belts in the seafood, shrimp, crab, fish, and frozen food processing industry through stages such as cutting, slicing, cooking, steaming, frying, and packaging

- In the pork, chicken, beef, etc. processing industry, conveyor belts are used

- In the vegetable, fruit, and cereal processing lines, etc., conveyor belts help transport raw materials from the preliminary processing and processing areas to the production and packaging stages

- Confectionery production lines use conveyor belts to move raw materials in each stage

- Application of food conveyor belts in the production lines of beverages, soft drinks, and beer from the preliminary processing to the packaging stage

Food conveyor belts are important and versatile equipment, bringing many benefits to businesses in many different industries. Choosing the right conveyor belt will help businesses optimize the production process, improve efficiency and product quality, while saving costs and ensuring labor safety.

Guide to choosing an Effective Food Conveyor

When choosing a food conveyor for your business, there are several important aspects to consider to ensure that it meets your specific needs and requirements.

- Hygiene and Cleanliness

The conveyor should be designed with materials and construction that can withstand regular cleaning and sanitizing. Stainless steel is a popular choice because of its durability and resistance to corrosion. Sealed bearings and other components should be used to minimize the possibility of bacteria buildup. Additionally, it is important to consider how easy it is to clean and sanitize the conveyor.

- Capacity and Efficiency

The conveyor should be able to handle the volume and weight of material that your business requires. Speed and incline should also be considered to ensure that the conveyor can move the product efficiently. Additionally, it is important to consider the capacity of the conveyor and how it will affect your overall production process. Think about how many products you need to transport per hour and how it will fit into your production process. Also, consider variations in the size, shape, and weight of the products being transported, as well as future expansion and scalability when selecting a conveyor.

- Durability and maintainability

The conveyor should be made of durable materials and construction to minimize the need for frequent repairs and maintenance. Stainless steel is also a popular choice here because of its durability and corrosion resistance. It should also be designed with accessibility in mind for easy cleaning and maintenance. This includes features such as removable belts and easily accessible parts for cleaning and maintenance.

- Customization and Integration

Your future conveyor should be customized to meet your specific needs and floor space requirements. Custom conveyor systems are a good option for facilities that cannot accommodate standard conveyor sizes or layouts. They include specialized modules that you can add or remove depending on the needs of your production process.

A new conveyor should integrate seamlessly with other equipment in your facility, such as packaging machines, to create an automated conveyor system. There is no point in investing in a new conveyor only to find out that the equipment you already have on your production line cannot work with it. Additional options, such as adding sensors or integrating with control systems, are also welcome on new conveyors.

- Safety and Ergonomics

Safety should be a top priority when selecting a food conveyor. It should comply with industry regulations and have features such as guardrails and emergency stop buttons to protect the operator and other workers from potential hazards such as pinch points and to minimize the risk of injury in the event of an emergency. Additionally, the conveyor should be designed with operator ergonomics in mind, such as height adjustment and easy-to-use controls, to minimize the risk of injury and fatigue while allowing for more comfortable and efficient operation.

- Consider Your Budget

When choosing a food conveyor, it is important to consider the total cost of ownership, which includes the initial cost of the conveyor, installation costs, and ongoing maintenance costs.

- The initial cost is the purchase price of the conveyor.

- Installation costs

- Maintenance costs include the cost of repairs, replacement parts, cleaning, and routine maintenance.

Return on investment (ROI) is a way to measure the financial performance of an investment, in this case a conveyor. It is calculated by taking the net benefit of the investment (cost savings or increased revenue) and dividing it by the total cost of the investment (initial cost, installation cost, and ongoing maintenance cost). A higher ROI means the investment is more profitable. By considering the long-term costs and potential ROI, you can make a more informed decision about whether a conveyor is a good investment for your business.

Food Conveyor standards and regulations to watch out for

Food conveyors play a vital role in ensuring food safety and production efficiency. Therefore, these equipment must comply with strict standards and regulations. Main standards and regulations

- Material standards:

- Materials in direct contact with food: Must be non-toxic materials that do not change the color or taste of food. Usually use stainless steel, HDPE plastic, PVC with food safety certification.

- Anti-corrosion: The conveyor belt must withstand humid environments, cleaning chemicals, high temperatures without being corroded.

- Easy to clean: The conveyor belt surface must be smooth, without edges for easy cleaning and disinfection.

- Design standards:

- The conveyor belt design must avoid dead corners and gaps so that bacteria have no place to stick.

- The conveyor belt parts must be easy to disassemble for cleaning and maintenance.

- International and Vietnamese standards

- International standards: ISO 22000: Food safety management system, HACCP (Hazard analysis and critical control point system).

- Vietnamese standards: TCVN 3148:1979 (General requirements for conveyor safety), regulations of the Ministry of Health on food safety and hygiene.

Intech Company produces reputable food conveyors at good prices

Intech Company is proud to be the leading reputable food conveyor manufacturer in Vietnam, with many years of experience in the field of design, manufacture and installation of conveyor systems for the food processing industry. We provide a variety of food conveyors to suit all customer needs. Intech's food conveyor products are made from high-quality materials, ensuring food safety and hygiene and high durability. We apply advanced technology in production, combined with a team of highly skilled engineers, to bring customers the best quality products at competitive prices.

Intech also provides consulting, design and installation services for complete conveyor systems, meeting all customer requirements. We are committed to bringing customers absolute satisfaction with product quality and service.

Choosing Intech, you will receive:

- High quality food conveyor products, food hygiene and safety.

- Competitive prices, suitable for all budgets.

- Professional consulting, design and installation services.

- Long-term, reputable warranty.

Contact Intech today for free consultation and detailed quotes on food conveyor products!

Contact information:

- Hotline: 0966 966 032

- Email: info@intech-group.vn

Những câu hỏi thường gặp

❖

Sản phẩm cùng loại khác