What is screw conveyor?

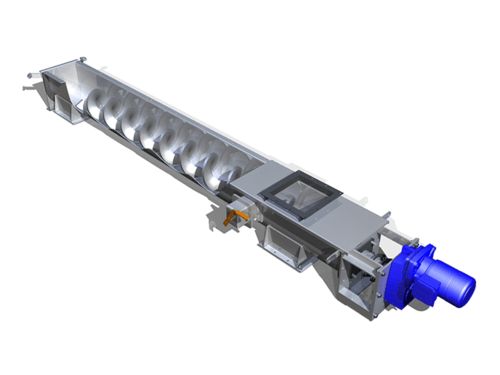

Screw conveyors, also known as drill conveyors, use a screw installed inside a tube or chute to transfer bulk, dry or liquid material.

Conveyor belts are manufactured based on actual use needs. To achieve the highest material conveying efficiency, it is necessary to choose the right type of conveyor to ensure the right specifications and configuration. Screw conveyors have a more special configuration than conventional conveyors. The technology used in screw conveyors is also complex and variable. Let's learn about screw conveyor through this article.

Screw conveyors also known as drill conveyors use a screw installed inside a tube or chute to transfer bulk, dry or liquid material. This conveyor can transfer different types of free-flowing as well as non-free-flowing materials such as powders, granules and pellets by using a spiral drill inside the housing. Flexible screw conveyor with conveyor cover, air inlet hopper, spiral drill...

Screw conveyors assist in the movement of items such as: packages, equipment, food or products from one area to another, often for the purpose of realizing automated production or finishing processes or semi-automatic. These conveyors can transport dry, bulk materials between trucks, crates, railcars, silos, hoppers and bins.

As a result, screw conveyors can be found in a wide range of industries and applications, such as: construction, oil and gas, mining, chemical, pharmaceutical, plastics, food processing and agriculture.

![Băng tải trục vít Băng tải trục vít]()

Screw conveyors work by moving bulk material from one location to another. They work on the screw principle. Archimedes' screw principle speaks for itself: When a rotating screw or drill is correctly installed inside a tube or cylinder, it can move water in the direction you've chosen. In addition, each time the screw rotates, it feeds new material into the tube.

Screw conveyors move materials at a predetermined flow rate. Depending on the application, this flow rate can be measured in cubic meters per hour. Their power can come from electricity, gravity, or the energy of another machine.

• Conveyor screw, also known as helical blade or helical shaft

• Screw trough or tubular housing

• Transmission components (shaft coupling and shaft seal or chain drive)

• Drive mechanism

The load screw (a helical blade coiled around the shaft) is located inside the tubular housing, where it is driven at one end and held at the other. The trough may or may not have a lid. Sometimes, screw conveyors have a helical blade, but no shaft. In this case, they are called shaftless screw conveyors, and the blade is driven at one end and free at the other.

The benefits of screw conveyors include: gentle material handling and mixing, system speed and efficiency, low investment costs, and system durability. Of all the screw conveyors have the lowest purchase and maintenance costs. They are also adaptable, customizable, and incredibly flexible. Screw conveyors also have the following benefits:

- Easy to clean:

Flexible screw conveyors can be suitable for small industrial units or assemblies. In addition, they can be easily cleaned after each transport by running the motor in reverse. They use a sealed tube to pass through the material, thus eliminating some of the problems associated with product dust. Simply put, screw conveyors are mechanically resistant to dust. The tube and screw of the conveyor can be easily bent within the mentioned radius. As a result, conveyors can be routed around fixed obstacles.

- Minimum maintenance:

Screw conveyors have only one moving part located at the top of the discharge head. Therefore, they are not prone to frequent damage and require only minimal maintenance.

- Easy to disassemble:

These conveyors can be easily disassembled by removing bolts, clean covers, and more. The housing of the screw conveyor is removed by releasing the joints connecting the discharge head and the hopper.

- Adjustable length:

The length of the conveying unit can be adjusted according to the transportation requirements of the industry such as water treatment, pharmaceutical, chemical, plastic and rubber, etc.

- Cost-effective:

Compared with traditional conveyor systems, screw conveyors are relatively inexpensive. Initial investment is low and this makes them an excellent equipment choice for applications.

To get the best screw conveyor for you, you need a reputable and professional manufacturer. Remember that the right manufacturer is not the one who can offer the lowest price, but the one who can offer the right type of conveyor belt to your specifications, standard requirements, timeline and budget. yours.

Intech Group has many years of experience in manufacturing quality conveyor belts, meeting the maximum needs of use, bringing the highest performance. Screw conveyors are manufactured by skilled engineers and workers, ensuring to bring customers the best quality products at the most suitable prices.

Interested in our conveyor products, contact today for the best advice and quote, Hotline: 024 66 806 795

What is screw conveyor?

Screw conveyors also known as drill conveyors use a screw installed inside a tube or chute to transfer bulk, dry or liquid material. This conveyor can transfer different types of free-flowing as well as non-free-flowing materials such as powders, granules and pellets by using a spiral drill inside the housing. Flexible screw conveyor with conveyor cover, air inlet hopper, spiral drill...

Applications of screw conveyors

Screw conveyors assist in the movement of items such as: packages, equipment, food or products from one area to another, often for the purpose of realizing automated production or finishing processes or semi-automatic. These conveyors can transport dry, bulk materials between trucks, crates, railcars, silos, hoppers and bins.

As a result, screw conveyors can be found in a wide range of industries and applications, such as: construction, oil and gas, mining, chemical, pharmaceutical, plastics, food processing and agriculture.

- In agriculture, screw conveyors are used as part of machinery, such as balers or threshers, to assist in the transportation of grain and fodder.

- In food processing, screw conveyors transport dry ingredients, such as nuts, salt and flour...

- The construction industry uses industrial screw conveyors to mix dry and wet ingredients to produce plaster or cement.

How does screw conveyor work?

Screw conveyors work by moving bulk material from one location to another. They work on the screw principle. Archimedes' screw principle speaks for itself: When a rotating screw or drill is correctly installed inside a tube or cylinder, it can move water in the direction you've chosen. In addition, each time the screw rotates, it feeds new material into the tube.

Screw conveyors move materials at a predetermined flow rate. Depending on the application, this flow rate can be measured in cubic meters per hour. Their power can come from electricity, gravity, or the energy of another machine.

Equipment components of screw conveyor:

• Conveyor screw, also known as helical blade or helical shaft

• Screw trough or tubular housing

• Transmission components (shaft coupling and shaft seal or chain drive)

• Drive mechanism

The load screw (a helical blade coiled around the shaft) is located inside the tubular housing, where it is driven at one end and held at the other. The trough may or may not have a lid. Sometimes, screw conveyors have a helical blade, but no shaft. In this case, they are called shaftless screw conveyors, and the blade is driven at one end and free at the other.

Benefits of using screw conveyors

The benefits of screw conveyors include: gentle material handling and mixing, system speed and efficiency, low investment costs, and system durability. Of all the screw conveyors have the lowest purchase and maintenance costs. They are also adaptable, customizable, and incredibly flexible. Screw conveyors also have the following benefits:

- Easy to clean:

Flexible screw conveyors can be suitable for small industrial units or assemblies. In addition, they can be easily cleaned after each transport by running the motor in reverse. They use a sealed tube to pass through the material, thus eliminating some of the problems associated with product dust. Simply put, screw conveyors are mechanically resistant to dust. The tube and screw of the conveyor can be easily bent within the mentioned radius. As a result, conveyors can be routed around fixed obstacles.

- Minimum maintenance:

Screw conveyors have only one moving part located at the top of the discharge head. Therefore, they are not prone to frequent damage and require only minimal maintenance.

- Easy to disassemble:

These conveyors can be easily disassembled by removing bolts, clean covers, and more. The housing of the screw conveyor is removed by releasing the joints connecting the discharge head and the hopper.

- Adjustable length:

The length of the conveying unit can be adjusted according to the transportation requirements of the industry such as water treatment, pharmaceutical, chemical, plastic and rubber, etc.

- Cost-effective:

Compared with traditional conveyor systems, screw conveyors are relatively inexpensive. Initial investment is low and this makes them an excellent equipment choice for applications.

Good price screw conveyor supplier

To get the best screw conveyor for you, you need a reputable and professional manufacturer. Remember that the right manufacturer is not the one who can offer the lowest price, but the one who can offer the right type of conveyor belt to your specifications, standard requirements, timeline and budget. yours.

Intech Group has many years of experience in manufacturing quality conveyor belts, meeting the maximum needs of use, bringing the highest performance. Screw conveyors are manufactured by skilled engineers and workers, ensuring to bring customers the best quality products at the most suitable prices.

Interested in our conveyor products, contact today for the best advice and quote, Hotline: 024 66 806 795