Outstanding advantages of gravity roller conveyor system

Gravity roller conveyor systems require no motor and are an economical fast solution for warehouses that need to move light to medium sized products around the worksite.

The gravity conveyor is by far the most used direct conveyor system in the industry. They are not only easy to implement, but also affordable and give users and warehouse managers a great incentive for their investment. In this article, we will provide you with the essential information about gravity conveyor systems, what defines this type of conveyor system, how they work and the benefits they can provide. for you.

Basic gravity roller conveyors use sliding wheels and rollers to move loads without the need for a source of mechanical power such as a motor. This type of conveyor typically moves items down an incline through a thrust along the conveyor.

Gravity roller conveyors are integral to all types of systems as they provide quick, affordable and easy-to-implement solutions for moving and handling large volumes of items. Gravity roller conveyor designs were some of the first designs designed for material handling.

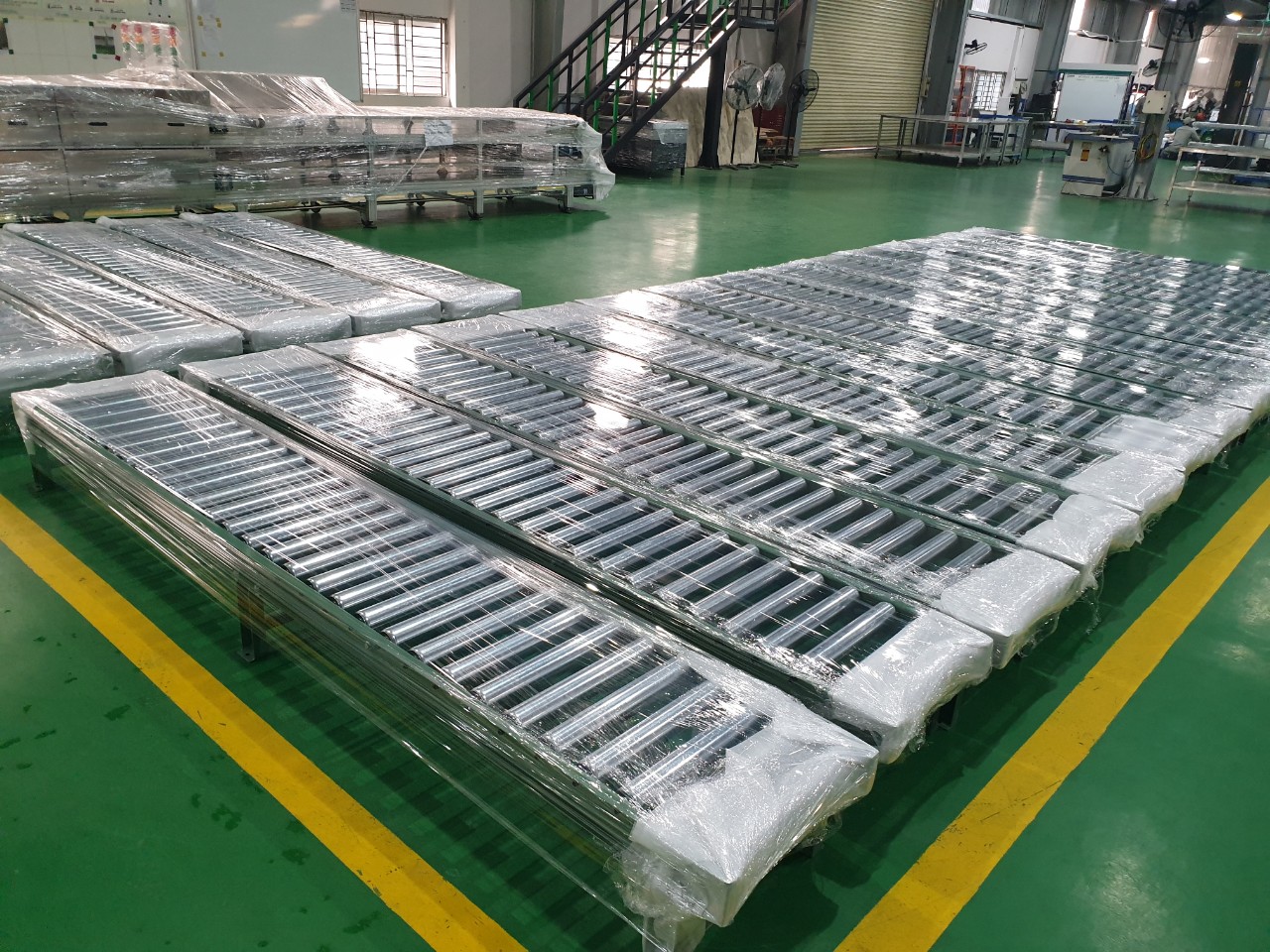

![Băng tải con lăn trọng lực]()

In essence, a gravity roller conveyor design is nothing more than a frame that rotates and uses momentum, whether it's someone pushing an item or gravity to slide material down along. Conveyor. The design is simple: imagine a ladder perpendicular, only instead of steps by conveyor rollers.

There are many advantages to having a gravity roller conveyor system in your warehouse. In addition to the fact that it optimizes your product handling, gravity roller conveyors can help you gain new customers. Here are some of the benefits of gravity roller conveyor systems.

1 - Reasonable conveyor price

Since they do not use a motor, gravity roller conveyors are extremely affordable. They are primarily created from steel, aluminum and plastic, materials that are commonly available and readily available.

2 - Flexibility

These types of systems are flexible, resilient and can adapt to your needs. In many cases they are implemented as makeshift conveyors and can be transported without any real challenge. Some can even be moved extremely quickly, not only in your warehouse but also in production areas, in case you need to move pallets or cartons.

3 - Easy to repair and maintain

Gravity roller conveyor designs are easy to maintain. Since they are mostly made of affordable, easily available materials, when a part fails, it is very simple to install a replacement part in the right place. You won't have to stop your entire operation, you won't have to find a professional, and in many cases it's just as easy to take out the broken part and click on a new one.

4 - Add-ons

Gravity roller conveyor components can be purchased and added to the original design. You can purchase accessories like curves, stands, mounts, rails, wheels, pop-up stops, and dozens of other features to customize your system.

Belt-driven roller conveyors, chain-driven roller conveyors, zero-pressure roller conveyors and a few other designs are high-tech systems that use electrical power to move items vertically on the assembly line. These are also great and can optimize your business. Their main advantage, when compared to gravity roller conveyor designs, is that you can transport items not only forward but also backward and inclined. They are also mostly automated.

However, they can be complex, involve a larger investment, and require more detailed design phases. Electric roller conveyors also require more professional assistance for maintenance and repair. For smaller, simple operations, we recommend investing in gravity roller conveyors where possible.

![Băng tải con lăn sử dụng điện năng]()

Gravity roller conveyor systems require no motor and are an economical fast solution for warehouses that need to move light to medium sized products around the worksite. They provide a great way to optimize your inventory in the blink of an eye.

Whether your operation is complex or simple, Intech Group will provide the right design, system and project management to give you the greatest ROI. We are committed to working with our customers for success! Contact us today to get started, Hotline: 024 66 806 795

Related Posts:

What is a Gravity Roller Conveyor System?

Basic gravity roller conveyors use sliding wheels and rollers to move loads without the need for a source of mechanical power such as a motor. This type of conveyor typically moves items down an incline through a thrust along the conveyor.

Gravity roller conveyors are integral to all types of systems as they provide quick, affordable and easy-to-implement solutions for moving and handling large volumes of items. Gravity roller conveyor designs were some of the first designs designed for material handling.

How does the gravity roller conveyor system work?

In essence, a gravity roller conveyor design is nothing more than a frame that rotates and uses momentum, whether it's someone pushing an item or gravity to slide material down along. Conveyor. The design is simple: imagine a ladder perpendicular, only instead of steps by conveyor rollers.

What are the advantages of gravity roller conveyor systems?

There are many advantages to having a gravity roller conveyor system in your warehouse. In addition to the fact that it optimizes your product handling, gravity roller conveyors can help you gain new customers. Here are some of the benefits of gravity roller conveyor systems.

1 - Reasonable conveyor price

Since they do not use a motor, gravity roller conveyors are extremely affordable. They are primarily created from steel, aluminum and plastic, materials that are commonly available and readily available.

2 - Flexibility

These types of systems are flexible, resilient and can adapt to your needs. In many cases they are implemented as makeshift conveyors and can be transported without any real challenge. Some can even be moved extremely quickly, not only in your warehouse but also in production areas, in case you need to move pallets or cartons.

3 - Easy to repair and maintain

Gravity roller conveyor designs are easy to maintain. Since they are mostly made of affordable, easily available materials, when a part fails, it is very simple to install a replacement part in the right place. You won't have to stop your entire operation, you won't have to find a professional, and in many cases it's just as easy to take out the broken part and click on a new one.

4 - Add-ons

Gravity roller conveyor components can be purchased and added to the original design. You can purchase accessories like curves, stands, mounts, rails, wheels, pop-up stops, and dozens of other features to customize your system.

Comparison of gravity roller conveyors and electric roller conveyors

Belt-driven roller conveyors, chain-driven roller conveyors, zero-pressure roller conveyors and a few other designs are high-tech systems that use electrical power to move items vertically on the assembly line. These are also great and can optimize your business. Their main advantage, when compared to gravity roller conveyor designs, is that you can transport items not only forward but also backward and inclined. They are also mostly automated.

However, they can be complex, involve a larger investment, and require more detailed design phases. Electric roller conveyors also require more professional assistance for maintenance and repair. For smaller, simple operations, we recommend investing in gravity roller conveyors where possible.

Electric roller conveyors

Why invest in a gravity roller conveyor system?

Gravity roller conveyor systems require no motor and are an economical fast solution for warehouses that need to move light to medium sized products around the worksite. They provide a great way to optimize your inventory in the blink of an eye.

Whether your operation is complex or simple, Intech Group will provide the right design, system and project management to give you the greatest ROI. We are committed to working with our customers for success! Contact us today to get started, Hotline: 024 66 806 795

Related Posts:

- The benefits of automatic sorting systems in today"s warehouses

- Advantages and disadvantages of automation in production

- When is the right time to bring the logistics industry into the process of automation?