Mesh conveyor belts are an efficient, flexible transportation solution, popular in many industries thanks to their airy, heat-resistant and easy-to-clean mesh structure. Learn about mesh conveyor belts, from structure, application to how to choose the right one.

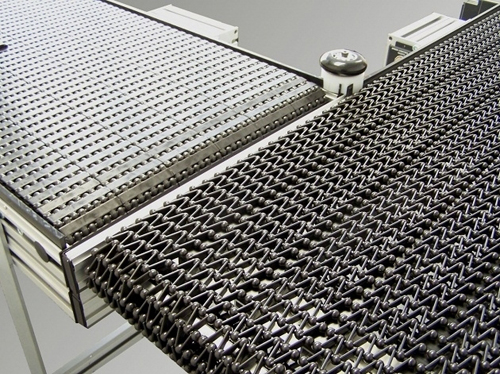

Mesh conveyors are unique product transport systems that use a woven or knitted mesh surface made from a variety of materials such as stainless steel, galvanized steel, or heat-resistant plastic. This special mesh structure creates openings that allow air, liquids, or heat to circulate easily. This makes mesh conveyors an ideal solution for industries that require ventilation, drainage, heat resistance, or ease of cleaning.

For example: In the food industry, stainless steel mesh conveyors transport fish through a freezer, the mesh allows cold air to pass through to quickly freeze the product.

![Mesh Conveyor Mesh Conveyor]()

Below is a list of popular types of mesh conveyors, classified based on materials, structures and practical applications:

Stainless steel mesh conveyor is a type of conveyor with a mesh surface made of stainless steel (stainless steel). This is a popular choice in many industries thanks to its durability, corrosion resistance and high hygiene.

Popular types of stainless steel mesh conveyors:

Outstanding features:

Advantages and disadvantages:

Common applications:

![Stainless steel mesh conveyor Stainless steel mesh conveyor]()

Steel mesh conveyor belt is designed to transport goods in environments requiring high mechanical strength and reasonable cost.

Popular types of steel mesh conveyor belts:

Outstanding features:

Advantages and disadvantages:

Applications:

![Steel Mesh Conveyor Belt Steel Mesh Conveyor Belt]()

Plastic mesh conveyor belts are a type of conveyor belt with a mesh surface made from engineering plastics (such as PE, PP, POM), designed to transport goods in environments that require light weight, chemical resistance or low cost.

Popular types of plastic mesh conveyor belts:

Outstanding features:

Advantages and disadvantages:

Common applications:

![Plastic mesh conveyor belts: Plastic mesh conveyor belts:]()

When using heat-resistant drying mesh conveyor belts, there are some important notes to ensure operating efficiency, equipment durability and safety during operation. Here are the points to note:

Here are some common mesh conveyor belt troubleshooting methods, causes and detailed solutions for you to easily apply:

Cause:

How to handle:

Prevention:

Cause:

How to handle:

Prevention:

Cause:

How to handle:

Cause:

How to handle:

Cause:

Remedy:

Prevention: Install overload protection (relay) for motor.

If you encounter another specific problem (such as loud noise, shaking) or need more detailed instructions for a case, contact the conveyor supplier for the best support.

![Conveyor motor does not run Conveyor motor does not run]()

If you are looking for a reputable mesh conveyor supplier, Intech Group is a reliable choice with quality products and professional services. Intech Group not only provides products but also aims to optimize the production process for businesses, helping to save costs, increase productivity and ensure sustainability.

Mesh conveyor prices vary widely and depend on many factors, including: the type of material you will use, whether it is stainless steel or plastic, the size and structure of the mesh also affect the overall price. The length and width of the mesh conveyor are important factors for an accurate mesh conveyor price quote.

Because of the variety of types and customization requirements, it is difficult to give an exact price.

Please provide detailed information about your needs, including material type, size, mesh structure, and customization requirements. We will quote the most accurate mesh conveyor price.

For more details, you can contact us via the official website or the company's Hotline: 0966 966 032 or email: info@intech-group.vn

What is Mesh Conveyor?

Mesh conveyors are unique product transport systems that use a woven or knitted mesh surface made from a variety of materials such as stainless steel, galvanized steel, or heat-resistant plastic. This special mesh structure creates openings that allow air, liquids, or heat to circulate easily. This makes mesh conveyors an ideal solution for industries that require ventilation, drainage, heat resistance, or ease of cleaning.

For example: In the food industry, stainless steel mesh conveyors transport fish through a freezer, the mesh allows cold air to pass through to quickly freeze the product.

Structure of mesh conveyor:

- The conveyor frame is the structure that supports the entire mesh conveyor system. It is usually made of steel, aluminum or stainless steel to ensure strength and durability.

- Conveyor belt: The main part, made of materials such as stainless steel, galvanized steel, or heat-resistant plastic. Woven, welded or cast into a mesh with open cells (cell size depends on usage needs).

- Electric motor: Provides energy to operate the conveyor, capacity depends on the load and length of the conveyor.

- Rollers: Placed at both ends of the conveyor (active roller and passive roller) to pull the mesh to move.

- Chain or belt: Connects the motor to the mesh, transmitting force to keep the mesh running continuously.

- Stainless steel box frame.

- Attach 2 load-bearing chains on both sides of the mesh to prevent displacement and deformation

- The horizontal connecting rod made of stainless steel helps prevent the mesh surface from sagging

- The motor and bearing system are covered to ensure production safety

- Electrical cabinet

Popular types of mesh conveyors today

Below is a list of popular types of mesh conveyors, classified based on materials, structures and practical applications:

1 - Stainless steel mesh conveyor: Heat-resistant, rust-proof, high durability

Stainless steel mesh conveyor is a type of conveyor with a mesh surface made of stainless steel (stainless steel). This is a popular choice in many industries thanks to its durability, corrosion resistance and high hygiene.

Popular types of stainless steel mesh conveyors:

- 304 stainless steel mesh conveyor: Good rust resistance, heat resistance up to ~400°C, popular in food and light industry.

- 316 stainless steel mesh conveyor belt: Superior corrosion resistance (especially with salt, acid), higher heat resistance than 304, used in harsh environments.

- 201 stainless steel mesh conveyor belt: Cheaper, but less rust resistance, suitable for dry environments.

Outstanding features:

- Corrosion resistance: Thanks to the Chromium and Nickel components in stainless steel, rust resistance in humid, acidic or salty environments.

- Heat resistance: Depending on the type of stainless steel (304: ~400°C, 316: ~500°C, 310: >800°C).

- Easy to clean: Smooth surface, non-stick, meets food safety standards.

- High durability: Good bearing capacity, long life in harsh conditions.

- Ventilation: Mesh holes support air, water or heat circulation.

Advantages and disadvantages:

- Advantages: Safe, clean, suitable for the food and medical industries. Durable in humid, high temperature environments. Easy to clean and maintain.

- Disadvantages: Higher cost than conventional steel or plastic conveyor belts. Heavier weight than plastic, requiring a sturdy support frame. Not suitable for prolonged extremely high temperatures (except stainless steel 310).

Common applications:

- Food industry: Drying (agricultural products, bread), freezing (meat, fish), washing (vegetables).

- Heavy industry: Heat treatment in furnaces (metals, ceramics). Transport in light chemical environments.

- Production lines: Transfer components, light products through stages.

Stainless steel 304 mesh conveyor belt effectively dries agricultural products

2 - Steel Mesh Conveyor Belt: Heavy load capacity, high durability, good price

Steel mesh conveyor belt is designed to transport goods in environments requiring high mechanical strength and reasonable cost.

Popular types of steel mesh conveyor belts:

- Carbon steel mesh conveyor belt (black steel): Uncoated steel, cheap, good load-bearing capacity but easy to rust in humid environments. Used in dry environments or transporting raw materials.

- Galvanized steel mesh conveyor belt: Steel coated with zinc, increases rust resistance, suitable for humid environments. Used in mining and construction.

- Alloy steel mesh conveyor belt: Steel mixed with Chromium, Manganese or Nickel, withstands higher heat and force. Used in furnaces or heavy industry.

- Hexagonal steel mesh conveyor belt: Mesh woven in a hexagonal pattern (rhombus/hexagonal), maximum ventilation. Suitable for drying or transporting large materials.

Outstanding features:

- High mechanical strength: Steel has the ability to withstand force, withstand large loads and is resistant to abrasion.

- Heat resistance: Steel usually withstands temperatures from 200°C - 600°C (depending on type and coating).

- Ventilation: Mesh holes support air, water or heat circulation.

- Lower cost than stainless steel: Suitable for applications that do not require high rust resistance.

- Flexible customization: Easy to process into many types of mesh (woven, welded, hexagonal).

Advantages and disadvantages:

- Advantages: Withstands heavy loads, suitable for heavy goods or harsh conditions. Cheaper than stainless steel mesh conveyor belts.

- Effective in medium temperature processes.

- Disadvantages: Easy to rust, not suitable for food

Applications:

- Mining: Transporting ore, coal, stone.

- Metal production: Feeding materials through furnaces or cooling.

- Construction: Transferring materials such as sand, gravel, cement in production lines.

- Agriculture: Drying agricultural products (corn, rice) in a not too humid environment.

Wire mesh conveyor belts effectively transport heavy materials in dry or less corrosive environments

3 - Plastic mesh conveyor belts: Lightweight, chemical resistant, easy to clean

Plastic mesh conveyor belts are a type of conveyor belt with a mesh surface made from engineering plastics (such as PE, PP, POM), designed to transport goods in environments that require light weight, chemical resistance or low cost.

Popular types of plastic mesh conveyor belts:

- PE (Polyethylene) plastic mesh conveyor belt: Good cold resistance, abrasion resistance, cheap. Used in freezing or transporting light food.

- PP (Polypropylene) plastic mesh conveyor belt: Good chemical resistance, heat resistance ~100°C. Used in the chemical industry, food washing.

- POM (Polyoxymethylene) plastic mesh conveyor belt: High hardness, better load bearing capacity than PE/PP. Used in medium load lines.

Outstanding features:

- Light weight: Plastic is lighter than metal, easy to install and transport.

- Chemical resistance: Not corroded by acid, alkali or salt (depending on the type of plastic).

- Rust-free: Suitable for humid environments or contact with water.

- Flexibility: Easy to cut, join or replace parts (especially with modular mesh).

- Limited heat resistance: Usually works well from -20°C to ~100°C (depending on the type of plastic).

Advantages and disadvantages:

- Advantages: Corrosion resistance: Does not rust, suitable for humid or chemical environments. Cheaper than stainless steel and some types of steel. Easy to customize, can be cut, joined or replaced quickly.

- Disadvantages: Poor heat resistance, not suitable for high temperatures (>100°C with PP, lower with PE). Cannot withstand goods that are too heavy like metal. Easily worn or deformed under great force.

Common applications:

- Food industry: Transporting vegetables and fruits during washing or drying. Food packaging (bottles, boxes) thanks to its flexibility.

- Chemical industry: Transporting raw materials in mild acid/alkaline environments.

- Light production lines: Transporting electronic components, plastic products.

- Agriculture: Screening or drying agricultural products (seeds, tubers).

Plastic mesh conveyor belt for transporting light goods in humid or chemical environments

Notes on using heat-resistant drying mesh conveyor belts

When using heat-resistant drying mesh conveyor belts, there are some important notes to ensure operating efficiency, equipment durability and safety during operation. Here are the points to note:

1. Check the heat resistance of the conveyor belt

- Make sure the ambient temperature and the drying product do not exceed the heat resistance threshold of the conveyor belt (usually from 100°C to 800°C depending on the material such as stainless steel mesh, PTFE, or Teflon). Exceeding the limit may damage the mesh or reduce its lifespan.

- Accurately determine the actual temperature of the drying material and do not choose a conveyor belt with an unnecessarily high heat resistance, as this will both increase costs and affect other features (such as tensile strength).

2. Select the appropriate mesh material

- Depending on the drying product (food, chemicals, agricultural products, etc.), select the appropriate mesh type:

- 304/316 stainless steel mesh: Good heat resistance (below 900°C), anti-corrosion, suitable for food and humid environments.

- PTFE/Teflon mesh: Heat resistance about 260-380°C, anti-stick, suitable for products that are easy to stick.

- Check the mesh size to ensure that the product does not fall through the gap during the drying process.

3. Adjust the load

- Do not exceed the design load of the conveyor belt. Overloading can cause mesh deformation, breakage or damage to the transmission system.

- Distribute the drying material evenly on the mesh surface to avoid stress concentration at one point.

4. Proper operation and maintenance

- Start-up: Only turn on the heating system (drying chamber) when the conveyor belt is running stably to avoid burning the mesh due to sudden temperature increase.

- Cleaning: Regularly clean the mesh to remove dirt, especially with sticky products, to maintain drying efficiency and ventilation.

- Maintenance: Periodically check parts such as motors, traction chains, and rollers to detect early wear or damage.

5. Ensure safety

- Equip a warning system (relay, buzzer) to detect problems such as sudden conveyor stop or overheating.

- Do not let the conveyor belt come into direct contact with liquids at high temperatures exceeding the heat tolerance threshold, as this may reduce the durability of the material.

- Adjust the conveyor speed and drying chamber temperature to suit the type of drying material to achieve optimal efficiency, avoiding uneven drying or burning of the product.

- Use a circulating fan (if available) to ensure even temperature distribution in the drying chamber.

Common mesh conveyor belt problems and effective solutions

Here are some common mesh conveyor belt troubleshooting methods, causes and detailed solutions for you to easily apply:

1 - Problem: Mesh conveyor belt is rusted

Cause:

- Using carbon steel mesh or galvanized steel in humid, acidic or salty environments.

- The zinc coating is worn out after a long time of use.

- Low-quality stainless steel mesh (such as 201 stainless steel) is not rust-proof enough in harsh conditions.

How to handle:

- Check the material: If it is ordinary steel, replace it with stainless steel mesh (304 or 316) to increase rust resistance.

- Cleaning: Use a rust remover solution (such as diluted phosphoric acid) and scrub with a steel brush, then rinse with clean water.

- Protective coating: Apply anti-rust paint or re-galvanize if the mesh cannot be replaced.

- Maintenance: Wipe dry after each shift, avoid leaving water on the mesh.

Prevention:

- Choose materials suitable for the environment (stainless steel 316 for salt and acid environments).

- Install a ventilation system to reduce humidity.

2. Problem: Deformed mesh

Cause:

- The load exceeds the mesh's load-bearing capacity (especially with plastic or thin steel mesh).

- High temperatures cause the material to expand or soften (such as PP plastic exceeding 100°C).

- Strong impacts or uneven pulling force from the transmission system.

How to handle:

- Check the load: Reduce the load or replace the mesh with a thicker, more resistant mesh (for example, from plastic to stainless steel).

- Adjust the temperature: If due to heat, reduce the drying temperature or use a material with higher heat resistance (such as stainless steel 310 instead of stainless steel 304).

- Repair: Cut off the heavily deformed part and replace it with a new mesh section (especially with modular mesh).

- Alignment: Adjust the roller and tensioner for even pulling force to avoid warping the mesh.

Prevention:

- Check the load and operating temperature regularly.

- Install a load sensor to warn when exceeding the threshold.

3. Other problems: The mesh conveyor is misaligned

Cause:

- The rollers or chains are not aligned.

- The mesh is sagging due to a loose tensioner.

- The load is unevenly distributed.

How to handle:

- Align the rollers: Use a measuring tape to ensure that the rollers are aligned.

- Increase the tension: Adjust the tensioner so that the mesh is not sagging.

- Load distribution: Place the product evenly on the mesh surface.

- Prevention: Periodically maintain the transmission system, check the mesh tension.

4. Problem: The mesh is clogged

Cause:

- Small products fall through the mesh holes (such as grains, powder) or dirt sticks (oil, sugar).

- The mesh hole size is not suitable for the product.

How to handle:

- Clean: Use high pressure water or a brush to clean the mesh.

- Replace mesh: Choose mesh with smaller holes if product is prone to falling, or larger if liquid needs to be drained.

- Pre-filter: Add a filter before product enters the conveyor.

- Prevention: Choose mesh with the correct hole size from the start.

5. Problem: Conveyor motor does not run

Cause:

- Motor overload due to jammed mesh or heavy load.

- Electrical circuit failure or broken belt/chain.

Remedy:

- Check load: Reduce load and check if mesh is jammed.

- Check power: Measure power source, replace fuse or repair circuit if necessary.

- Replace: Repair or replace belt/chain if broken.

Prevention: Install overload protection (relay) for motor.

If you encounter another specific problem (such as loud noise, shaking) or need more detailed instructions for a case, contact the conveyor supplier for the best support.

Quick troubleshooting of mesh conveyor is essential to ensure uninterrupted production operations.

Where to buy mesh conveyor?

If you are looking for a reputable mesh conveyor supplier, Intech Group is a reliable choice with quality products and professional services. Intech Group not only provides products but also aims to optimize the production process for businesses, helping to save costs, increase productivity and ensure sustainability.

Intech Group's strengths:

- Flexible customization: Intech Group designs mesh conveyors according to requirements with size, load and operating environment.

- Modern technology: Using advanced machinery to ensure product accuracy and durability.

- Comprehensive service: From consulting, surveying, designing to installation and maintenance, Intech is committed to providing maximum support to customers.

- Guaranteed quality: Products meet international standards, especially food safety standards when using stainless steel mesh.

Mesh Conveyor Price:

Mesh conveyor prices vary widely and depend on many factors, including: the type of material you will use, whether it is stainless steel or plastic, the size and structure of the mesh also affect the overall price. The length and width of the mesh conveyor are important factors for an accurate mesh conveyor price quote.

Because of the variety of types and customization requirements, it is difficult to give an exact price.

- The price of stainless steel mesh conveyor ranges from 30,000,000 - 500,000,000 VND.

- The price of plastic mesh conveyor ranges from 20,000,000 - 300,000,000 VND

Please provide detailed information about your needs, including material type, size, mesh structure, and customization requirements. We will quote the most accurate mesh conveyor price.

For more details, you can contact us via the official website or the company's Hotline: 0966 966 032 or email: info@intech-group.vn

Những câu hỏi thường gặp

❖

Sản phẩm cùng loại khác