Features of bottling filling machine you should know:

Bottle filling machines allow you to express your creativity through our versatility. Nearly anything is possible, from unique bottle shapes and decorations to unique caps, thanks to different options:

- With a range from 12000 bottles per hour.

- Super clean and sterile filling options.

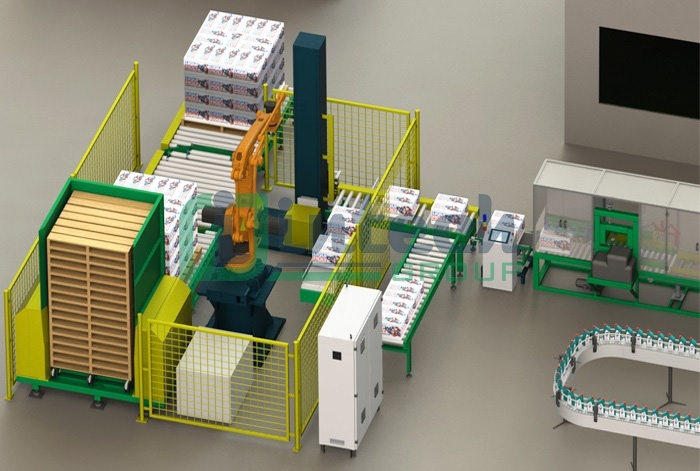

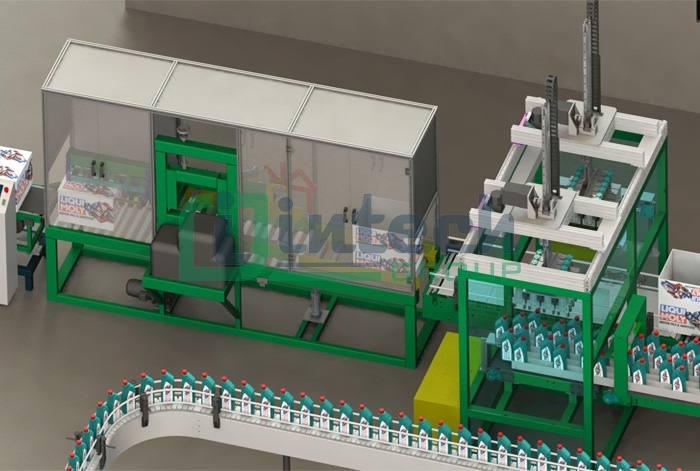

Our bottle filling lines offer solutions for small and medium production operations where frequent changes are required for highly segmented markets, as well as for larger volumes. Flexibility and scalability are at the forefront of every project to provide manufacturers with the ability to respond to market developments and needs as well as new product developments. The filling line adopts technology, scientific and reasonable design, beautiful appearance, complete function, convenient operation and maintenance, and high degree of automation.

Line feature bottling filling

- Our bottle filling line is made of high quality materials and can be operated at room temperature or hotter.

- It is suitable for the production of glass bottled juice, tea drinks, wine, water and other beverages.

- In case of changing bottle fittings, the discharge, filling, and sealing can be applied to bottles of different specifications and sizes.

- The liquid level in the material tank is controlled automatically, there is no bottle no filling, no bottle no capping function.

- It also has the function of stopping when the bottle is dislocated or when the cap is missing

- The cap sorter is installed in the low position and the cap is distributed horizontally.

System specs:

| Product Specifications | 0,6-0,8-1 liter pet |

| Filling capacity | 12.000 Pet /hour |

| Packing capacity | 25pallet/hour ~ 500carton /hour |

Intech Group provides reputable bottling line

We can supply and install complete bottling and filling lines, from start to finish, for all kinds of user requirements.

Our team of engineers at Intech Group focus on:

- Development of highly efficient packaging and filling lines to achieve the best solution that provides excellent quality, cost-effectiveness and production performance.

- Integrated development on existing complete filling lines to increase production rate, improve quality.

- Provide efficient, personalized service built on your specific customization requirements in liquid filling machines to fit your production and marketing goals.

Những câu hỏi thường gặp

❖

Sản phẩm cùng loại khác