In the electronics manufacturing industry, the washing machine assembly, testing and packaging line plays a core role in ensuring productivity, quality and production efficiency. It is an automated or semi-automated system, designed to handle the stages from assembling parts, testing functions to packaging the final product.

![Dây chuyền lắp ráp đảm bảo hiệu suất sản xuất máy giặt tối ưu Dây chuyền lắp ráp đảm bảo hiệu suất sản xuất máy giặt tối ưu]()

Intech Group's washing machine production line solution is designed to optimize the entire process, from assembling parts, testing quality to packaging products. The main benefits include:

![Dây chuyền đóng gói máy giặt tiết kiệm thời gian và chi phí lao động Dây chuyền đóng gói máy giặt tiết kiệm thời gian và chi phí lao động]()

The washing machine assembly, testing and packaging line provided by Intech Group is a key production system in electrical machinery factories, designed with the following superior features:

![Dây chuyền lắp ráp máy giặt tự động Dây chuyền lắp ráp máy giặt tự động]()

Intech Group has affirmed its position as a reliable partner in the field of providing automation solutions thanks to:

If you are looking for a comprehensive solution to upgrade your assembly line, Intech Group is a reliable choice. Contact us for detailed advice and quotation, Hotline: 0966 966 032

Benefits of the assembly, testing and packaging line automation solution

Intech Group's washing machine production line solution is designed to optimize the entire process, from assembling parts, testing quality to packaging products. The main benefits include:

- Increased production efficiency: The automation system minimizes manual operation time, ensuring a continuous and stable production process. This helps to significantly increase output, meeting large market demand.

- Save labor costs: With a closed and automatic process, the line reduces dependence on manual labor, thereby cutting down on personnel costs while maintaining high efficiency.

- Ensure consistent quality: Synchronization between stages helps to strictly control quality, ensuring 100% of products meet standards before leaving the factory.

- Optimize management: Integrated QLSX software allows real-time monitoring of production progress, providing detailed data by shift, day, week, month or year, supporting management to make quick and accurate decisions.

Outstanding features of washing machine assembly, testing and packaging lines

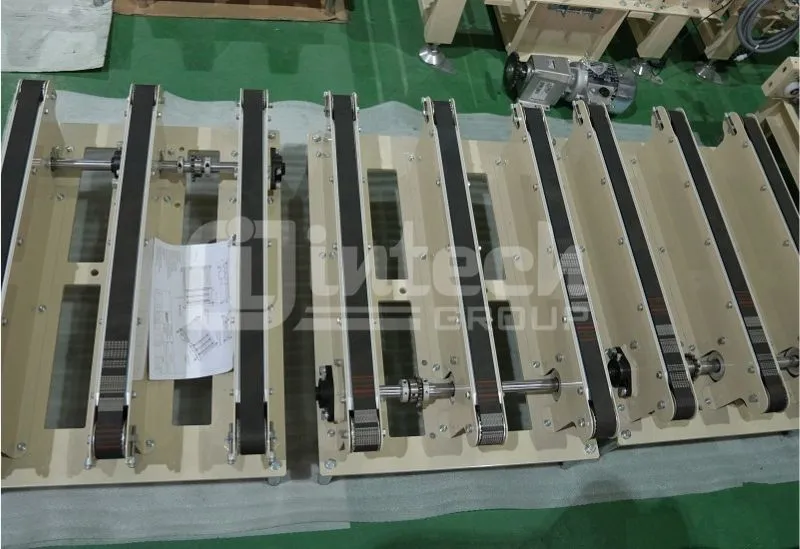

The washing machine assembly, testing and packaging line provided by Intech Group is a key production system in electrical machinery factories, designed with the following superior features:

- Fully automated process: From the assembly of components (such as motors, washing drums, control panels) to functional testing and packaging, the entire process is automated, minimizing manual intervention. This not only increases speed but also reduces the risk of errors.

- Automatic product movement: Products are automatically transported through work stations on belt conveyors and roller conveyors, allowing workers to operate in place without moving. This saves time, increases accuracy and reduces worker fatigue.

- Synchronization of stages: The stages are coordinated smoothly, ensuring consistent time and quality. For example, after assembly, washing machines are automatically transferred to an inspection station to verify functions such as washing, spinning, or draining, before being sent to packaging.

- Advanced production management software: The QLSX system provides real-time monitoring capabilities, displaying key performance indicators (KPIs) such as output, defect rates, and completion times. The software also has the ability to alert when progress is slow or problems are detected, helping managers make timely adjustments to meet production goals.

- Customization capabilities: The line can be flexibly designed according to the specific needs of each factory, from small scale to large production lines, ensuring it is suitable for different types of washing machines (top-load, front-load, or industrial washing machines).

Why choose Intech Group for assembly lines?

Intech Group has affirmed its position as a reliable partner in the field of providing automation solutions thanks to:

- Outstanding quality: The production line system is made from durable materials, integrated with advanced technology, ensuring stability and long life.

- Competitive price: Intech Group provides solutions at reasonable costs, suitable for the budgets of many businesses, from medium to large scale.

- Customized service and technical support: A team of experienced engineers is ready to design, install and maintain the system according to specific requirements, ensuring optimal operating efficiency.

If you are looking for a comprehensive solution to upgrade your assembly line, Intech Group is a reliable choice. Contact us for detailed advice and quotation, Hotline: 0966 966 032

Những câu hỏi thường gặp

❖

Sản phẩm cùng loại khác