Traditional warehouse systems, with fixed shelves and manual or semi-automated processes, often have limitations in storage density, causing waste of space. At the same time, the speed of import and export of goods is delayed due to dependence on manual labor or bulky equipment, reducing efficiency and increasing operating costs.

Robot Shuttle, an advanced automation technology, was born as a breakthrough to solve these challenges. With the ability to move flexibly, optimize storage space and increase the speed of goods processing, Robot Shuttle provides a smart warehousing solution, meeting the increasing needs of e-commerce and modern supply chains.

Robot Shuttle is also known as an automatic Shuttle vehicle running on rails in warehouse racking systems, specializing in loading, unloading, moving and storing palletized goods. Robot shuttle is the core part of the Radio Shuttle shelf system, helping to optimize warehouse space, increase the productivity of goods import and export and minimize labor costs.

![Robot Shuttle Robot Shuttle]()

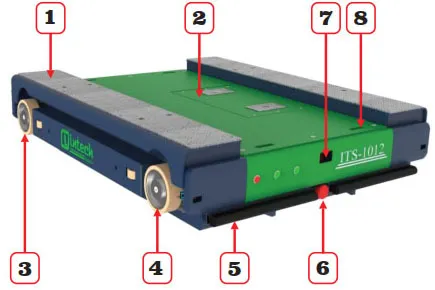

Includes the following 8 parts:

1 - Pallet lifting and lowering unit: Used to lift and lower pallets, helping the robot to pick up and place goods accurately.

2 - Lithium battery unit: Provides energy for the robot to operate continuously with high efficiency.

3 - Guide wheel unit: Supports the robot to move stably and accurately on the rail.

4 - Drive wheel unit: Creates thrust to help the robot move.

5 - Safety sensor: Detects obstacles or people in the operating area, helping the robot stop automatically to ensure safety.

6 - Emergency stop button: Physical button that allows humans to stop the robot immediately in case of emergency.

7 - Distance sensor: Helps the robot measure the distance to other objects, ensuring the movement and operation process takes place smoothly, without collision.

8 - Pallet check sensor: Check the position and status of the pallet, ensuring that the robot picks and places it in the correct position.

![Robot Shuttle Robot Shuttle]()

Robot shuttle is an autonomous device designed to move on specialized shelf lanes, performing the tasks of importing, stacking and unloading goods automatically. This technology helps optimize storage space and increase warehouse management efficiency.

The robot shuttle operates based on the principle of using an electric motor to move pallets containing goods on a rail system inside the storage shelves.

Detailed operating principle:

Robot Shuttle has many practical applications in fields that require efficient storage and transportation of goods, especially in the context of e-commerce and logistics development. Here are some prominent applications:

![Robot Shuttle Robot Shuttle]()

The role of Robot Shuttle is indispensable in building smart warehouses in the future, becoming an inevitable solution to meet the increasing demands of e-commerce and modern logistics. Businesses need to proactively learn and invest in this technology to improve their competitiveness.

Intech Group is proud to be the leading unit in Vietnam, specializing in providing and installing high-quality Robot Shuttle systems, helping your business solve all logistics challenges. With experience and a team of dedicated experts, we are committed to providing the most optimal solution, helping you save costs, improve productivity and create sustainable competitive advantages.

Contact Intech Group now for detailed advice and to own a smart and effective warehouse solution.

Robot Shuttle, an advanced automation technology, was born as a breakthrough to solve these challenges. With the ability to move flexibly, optimize storage space and increase the speed of goods processing, Robot Shuttle provides a smart warehousing solution, meeting the increasing needs of e-commerce and modern supply chains.

What is Robot Shuttle?

Robot Shuttle is also known as an automatic Shuttle vehicle running on rails in warehouse racking systems, specializing in loading, unloading, moving and storing palletized goods. Robot shuttle is the core part of the Radio Shuttle shelf system, helping to optimize warehouse space, increase the productivity of goods import and export and minimize labor costs.

Main structure of Robot Shuttle

Includes the following 8 parts:

1 - Pallet lifting and lowering unit: Used to lift and lower pallets, helping the robot to pick up and place goods accurately.

2 - Lithium battery unit: Provides energy for the robot to operate continuously with high efficiency.

3 - Guide wheel unit: Supports the robot to move stably and accurately on the rail.

4 - Drive wheel unit: Creates thrust to help the robot move.

5 - Safety sensor: Detects obstacles or people in the operating area, helping the robot stop automatically to ensure safety.

6 - Emergency stop button: Physical button that allows humans to stop the robot immediately in case of emergency.

7 - Distance sensor: Helps the robot measure the distance to other objects, ensuring the movement and operation process takes place smoothly, without collision.

8 - Pallet check sensor: Check the position and status of the pallet, ensuring that the robot picks and places it in the correct position.

Superior features of Robot Shuttle

Robot shuttle is an autonomous device designed to move on specialized shelf lanes, performing the tasks of importing, stacking and unloading goods automatically. This technology helps optimize storage space and increase warehouse management efficiency.

- Operating capacity: Moving pallets inside does not require a specialized forklift. Simultaneously and efficiently move goods

- Minimize damage to goods: Move and stop accurately

- Independent operation: Each Shuttle vehicle is capable of operating independently on each floor

- Flexible operation: Compatible with both FIFO and LIFO import and export methods

- Capable of continuous import and export of pallets

- Diverse models: Diverse vehicle sizes, suitable for many different pallet sizes

- Load capacity: Goods load capacity can be up to 1500kg

- Automatic pallet check: Remote pallet detection, quick detection helps reduce operating cycles

- Operating time: Continuous operation for 8 to 10 hours

- Remote Control: Control the Shuttle Robot by 1 touch with a screen displaying operating status. Can control multiple Shuttle vehicles simultaneously. Easy to operate and operate accurately

How the Robot Shuttle works in the storage system

The robot shuttle operates based on the principle of using an electric motor to move pallets containing goods on a rail system inside the storage shelves.

Detailed operating principle:

- Receiving and moving pallets: When a pallet is put into the system, the forklift will place it on the first rail of the shelf. The shuttle will now move from the end of the shelf, move to the position of that pallet and lift the pallet up.

- Storage: The shuttle will carry the pallet deep inside the shelf, to the predetermined empty storage location. After arriving, it will lower the pallet to the last position and automatically turn back to continue the cycle.

- Retrieving goods: When it is necessary to retrieve goods, the shuttle will receive the command, move to the correct position of the pallet to be retrieved, lift the pallet up and carry it to the end of the shelf. Here, the forklift will take the pallet out of the shelf system.

How the Robot Shuttle works to transport pallets in a high-density storage system

Comparison of Robot Shuttle and Traditional Forklift

| Features | Robot Shuttle | Traditional Forklift |

| Operating principle | Automatically moves on rails inside the rack to pick up and place pallets. Operates independently. | Operated by humans. Moves on wide aisles. |

| Storage space | Optimizes space. Minimizes aisles, maximizes shelf depth, increases storage density many times. | Space-consuming. Requires wide aisles for vehicles and operations, reduces storage density. |

| Performance | High productivity. Operates 24/7 continuously, stable speed, no fatigue. | Limited by humans. Speed depends on the driver's skills and health. |

| Safety | High safety. Minimizes the risk of accidents and collisions because there are no humans operating directly in the rack lane. | High risk. Collisions and accidents are likely to occur due to driver error or narrow spaces. |

| Accuracy | Absolute accuracy. Sensor system helps pick and place pallets in the correct position, minimizing damage to goods. | There are errors. Accuracy depends on the experience and concentration of the driver. |

| Operating | Environment Flexible. Works well in deep cold storage environments. | Limited. Requires specialized forklifts for each type of environment (e.g. cold storage). |

| Cost | High initial investment. However, long-term efficiency in terms of labor and space. | Low initial investment. Higher operating, maintenance and labor costs in the long run. |

Outstanding benefits of Robot Shuttle

- Increase storage density: Robot Shuttle allows maximum utilization of space in the depth of the warehouse. By minimizing the aisles for forklifts, this system can increase the capacity of goods by up to 85-90%, many times higher than traditional warehouses.

- Increase the speed of import and export: Robots operate automatically, continuously 24/7 with high speed and accuracy, eliminating waiting time and minimizing human errors. This significantly shortens order processing time and increases overall work efficiency.

- Improve labor safety: By replacing humans and forklifts in narrow lanes, Robot Shuttle helps eliminate the risk of collision and labor accidents, creating a safer working environment for employees.

- Reduced operating costs: In the long run, using robots helps businesses save significantly on labor costs, reduce forklift maintenance costs and limit damage to goods, thereby optimizing profits.

- Flexible and easy to expand: The Robot Shuttle system can be programmed to handle many different import and export modes (FIFO/LIFO) and can be easily expanded by adding robots or shelves as storage needs increase.

- Operating in harsh environments: Robot Shuttle is capable of working stably in special environments such as deep cold storage with temperatures up to -30°C, which is difficult for traditional forklifts to meet.

Practical applications of Robot Shuttle

Robot Shuttle has many practical applications in fields that require efficient storage and transportation of goods, especially in the context of e-commerce and logistics development. Here are some prominent applications:

- E-commerce: Shuttle Robots are used in warehouses of companies such as Amazon or Lazada to quickly process millions of orders, optimize storage space and speed up delivery.

- Logistics and distribution: This system supports large distribution centers, automatically manages pallets of goods, reduces import and export time and ensures that goods are transported accurately to the required locations.

- Food and beverage industry: Shuttle Robots operate stably in cold environments (such as freezers at -30℃), helping to store and transport frozen foods or drinks without interrupting the cold chain.

- Industrial production: In automated factories, Shuttle Robots are used to move raw materials or finished products between production areas and warehouses, increasing line efficiency.

- Automated warehouse: This system is integrated into smart warehouses, supporting both LIFO (last in, first out) and FIFO (first in, first out) modes, suitable for the diverse needs of businesses.

Upgrading the supply chain with Intech Group's Robot Shuttle

The role of Robot Shuttle is indispensable in building smart warehouses in the future, becoming an inevitable solution to meet the increasing demands of e-commerce and modern logistics. Businesses need to proactively learn and invest in this technology to improve their competitiveness.

Intech Group is proud to be the leading unit in Vietnam, specializing in providing and installing high-quality Robot Shuttle systems, helping your business solve all logistics challenges. With experience and a team of dedicated experts, we are committed to providing the most optimal solution, helping you save costs, improve productivity and create sustainable competitive advantages.

Contact Intech Group now for detailed advice and to own a smart and effective warehouse solution.

- Hotline: 0966 966 032 or 0983 113 387

- Email: info@intech-group.vn

- Address: Lot 6, Lai Xa Industrial Park, Tay Tuu Ward, Hanoi City

Những câu hỏi thường gặp

❖

Sản phẩm cùng loại khác