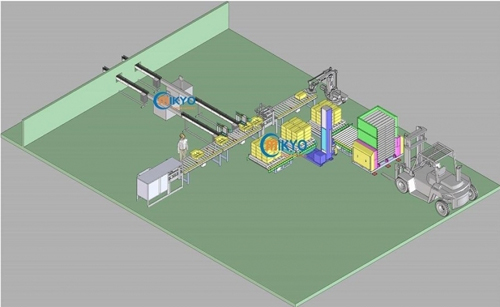

With many years of experience in the automation industry, we have launched many automatic packaging lines that meet international standards and are highly trusted by customers. To serve the manufacturing industry, automatic lines operate continuously to help improve packaging efficiency and ensure product quality during the packaging process.

An automatic packaging line is an automatic or semi-automatic system used to package products efficiently and quickly in the production or packaging process. This line is often used in industries such as food, pharmaceuticals, beverages, electronics and many others to increase productivity, reduce human error and ensure product quality.

An automatic line can include equipment such as packaging machines, strapping machines, carton sealers, barcode printers, quality inspectors, pallet wrappers and automated or robotic systems for lifting, stacking, and packaging products. This helps optimize the production process and reduce production time, helping businesses save costs and create reliable products for the market.

![]()

![]()

There are many benefits of applying technology to your packaging process, including:

Automated packaging lines play an important role in the production and packaging process, helping to increase efficiency, reduce errors and save labor costs. Here are some examples:

The food processing industry uses a wide range of food packaging equipment and machinery. Food processing line equipment and solutions are used to enhance the quality and shelf life of food while packaging equipment is used to safely package prepared food.

Common packaging equipment used in food processing include food vacuum packaging machines, carton sealers, and case strapping machines. Filling machines are mainly used for liquid food products. These can include aseptic fillers, piston fillers, volumetric fillers, and robotic fillers.

Automated beverage packaging lines need to provide high quality output to ensure they meet quality and safety standards. Our automated packaging solutions are designed to help improve the speed, productivity, and efficiency of your production line.

A pharmaceutical packaging line is an important automation system in the pharmaceutical manufacturing and packaging process. This helps to ensure that the final product meets the quality and safety standards in the pharmaceutical industry. Complete pharmaceutical packaging lines include carton box packing machines, carton sealers, box strapping machines, and palletizers.

You must schedule regular maintenance for your lines to ensure they maintain their efficiency over a long period of time. Poor maintenance of your lines causes them to malfunction and break down frequently, resulting in downtime and repair costs. There are different maintenance procedures for your lines. Here is a detailed guide:

This is the maintenance procedure you must perform regularly to avoid any malfunctions and breakdowns of your packaging lines. Some preventive maintenance measures include:

These are maintenance activities that you perform on the packaging line according to the manufacturer's instructions. They include:

Packaging involves various stages and specialized equipment to properly contain, protect, and present a product to the consumer, demonstrating its complexity. Understanding the complete packaging line as well as the different types of equipment involved is essential to optimizing efficiency, quality, and cost savings.

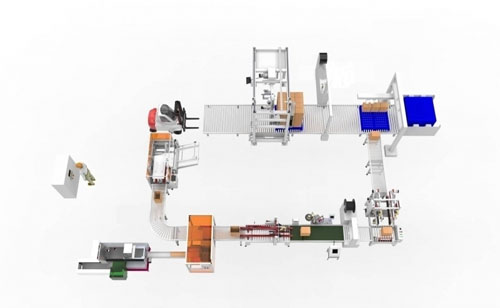

A typical packaging line consists of several interconnected machines and components that work in harmony to achieve the desired packaging result. The specific equipment and layout may vary depending on the product, packaging format, and production requirements. Here is an overview of a typical line:

Several ancillary equipment components are often integrated into the packaging line, in addition to the main packaging machines, to improve efficiency, automation, and overall performance:

Packaging lines can range from manual or semi-automated operations to highly automated and integrated systems. This depends on the production volume, product complexity, and desired level of efficiency. Automated lines typically incorporate:

For some companies, the idea of using large machinery can seem quite daunting. At Intech, we try to alleviate any concerns by working closely with you to ensure you install the right packaging machine to suit your requirements. Our technical team will discuss your exact requirements and then help advise on the best option available. Once confirmed, we will ensure prompt delivery and provide full installation if you wish.

Contact us today to discuss in more detail and find out how Intech Group can help you automate your packaging process.

What is an automatic packaging line?

An automatic packaging line is an automatic or semi-automatic system used to package products efficiently and quickly in the production or packaging process. This line is often used in industries such as food, pharmaceuticals, beverages, electronics and many others to increase productivity, reduce human error and ensure product quality.

An automatic line can include equipment such as packaging machines, strapping machines, carton sealers, barcode printers, quality inspectors, pallet wrappers and automated or robotic systems for lifting, stacking, and packaging products. This helps optimize the production process and reduce production time, helping businesses save costs and create reliable products for the market.

Intech automatic packaging line specifications:

Features of an automated packaging line:

- Highly automated system, stable, durable, reliable operation line

- User-friendly control panel, easy to use

- Flexible design, suitable for many packaging sizes

- Easy to clean and maintain

Benefits of implementing an automated packaging line

There are many benefits of applying technology to your packaging process, including:

- Reducing the risk of repetitive strain injuries

- Eliminating potential bottlenecks

- Improving production speed

- Eliminating downtime

- Increasing employee morale

- Better customer service

Some examples of commonly used automated packaging lines today

Automated packaging lines play an important role in the production and packaging process, helping to increase efficiency, reduce errors and save labor costs. Here are some examples:

- Food Industry

The food processing industry uses a wide range of food packaging equipment and machinery. Food processing line equipment and solutions are used to enhance the quality and shelf life of food while packaging equipment is used to safely package prepared food.

Common packaging equipment used in food processing include food vacuum packaging machines, carton sealers, and case strapping machines. Filling machines are mainly used for liquid food products. These can include aseptic fillers, piston fillers, volumetric fillers, and robotic fillers.

- Beverage Industry

Automated beverage packaging lines need to provide high quality output to ensure they meet quality and safety standards. Our automated packaging solutions are designed to help improve the speed, productivity, and efficiency of your production line.

- Carton Erector: We develop carton erecting solutions to open, fold and shape the packaging, preparing the product to be packed inside

- Carton Sealer: Our smart packaging solution can place each beverage container into a carton, ready for the next stage of the production process.

- Strapper: To ensure that the product is ready for distribution, the strapper helps to secure and protect the carton, making it easy to palletize efficiently.

- Product Handling: To ensure that your product moves efficiently throughout the production process, we build a product handling conveyor system to meet your requirements.

- Pharmaceutical Industry

A pharmaceutical packaging line is an important automation system in the pharmaceutical manufacturing and packaging process. This helps to ensure that the final product meets the quality and safety standards in the pharmaceutical industry. Complete pharmaceutical packaging lines include carton box packing machines, carton sealers, box strapping machines, and palletizers.

Effective packaging line maintenance guide

You must schedule regular maintenance for your lines to ensure they maintain their efficiency over a long period of time. Poor maintenance of your lines causes them to malfunction and break down frequently, resulting in downtime and repair costs. There are different maintenance procedures for your lines. Here is a detailed guide:

Preventive maintenance of packaging lines

This is the maintenance procedure you must perform regularly to avoid any malfunctions and breakdowns of your packaging lines. Some preventive maintenance measures include:

- Perform scheduled inspections

- Regularly change worn parts

- Stock parts are likely to wear out quickly

- Schedule timely machine lubrication

- Monitor, record and report minor problems in operation and follow up for appropriate corrective action

Pre-planned maintenance:

These are maintenance activities that you perform on the packaging line according to the manufacturer's instructions. They include:

- Replace lubricants on a scheduled basis after a specified period of machine operation

- Replace rapidly worn parts after a specified period of time or after operating the machine according to instructions

- Follow operating conditions as described by the manufacturer

- Maintain standard pressure, oil, and lubricant at the specified levels according to instructions

Standard Product Packaging Process

Packaging involves various stages and specialized equipment to properly contain, protect, and present a product to the consumer, demonstrating its complexity. Understanding the complete packaging line as well as the different types of equipment involved is essential to optimizing efficiency, quality, and cost savings.

- Complete Packaging Line

A typical packaging line consists of several interconnected machines and components that work in harmony to achieve the desired packaging result. The specific equipment and layout may vary depending on the product, packaging format, and production requirements. Here is an overview of a typical line:

- Product Handling and Feeding: This stage includes equipment such as hoppers, vibrating feeders, or conveyor systems to deliver products into the packaging line in a consistent and controlled manner.

- Primary packaging: At this stage, the product is immediately packaged in a container such as a bag, pouch, bottle, or carton.

- Secondary packaging: After primary packaging, workers (or machines) may further package the product in larger cartons or boxes for shipping and distribution.

- Coding and labeling: Coding and labeling equipment applies important information such as lot codes, expiration dates, barcodes, and product labels to primary or secondary packaging.

- Quality inspection: Inline quality inspection systems, such as metal detectors, checkweighers, and visual inspection systems, ensure product integrity, weight accuracy, and packaging quality.

- End-of-Line Operations: This stage involves final processing and distribution preparation equipment, such as: Palletizers, Shrink Wrappers, Case Sealers, etc.

- Ancillary Equipment

Several ancillary equipment components are often integrated into the packaging line, in addition to the main packaging machines, to improve efficiency, automation, and overall performance:

- Conveyors: Used to transport products and packaging between different stages of the line.

- Accumulation Conveyors: Allow temporary storage and buffering of products or packages to maintain consistent flow.

- Sorters and Sorters: Used to separate or route products or packages based on specific criteria.

- Robots and AGVs: Used to handle, load, and unload products.

- Level of Automation

Packaging lines can range from manual or semi-automated operations to highly automated and integrated systems. This depends on the production volume, product complexity, and desired level of efficiency. Automated lines typically incorporate:

- Programmable logic controllers (PLCs): Used to control and coordinate the operation of various machines and components in the line

- Human-machine interfaces (HMIs): Allow operators to monitor and adjust line parameters

- Machine vision systems: Used for quality inspection, code verification, and packaging defect detection.

- Data collection and analysis: Collect and analyze data from multiple points in the line to optimize performance and predictive maintenance.

Intech Group offers highly efficient automated packaging lines

For some companies, the idea of using large machinery can seem quite daunting. At Intech, we try to alleviate any concerns by working closely with you to ensure you install the right packaging machine to suit your requirements. Our technical team will discuss your exact requirements and then help advise on the best option available. Once confirmed, we will ensure prompt delivery and provide full installation if you wish.

Contact us today to discuss in more detail and find out how Intech Group can help you automate your packaging process.

- Hotline: 024 66 806 795

- Address: Lot 6, Lai Xa Industrial Cluster, Tay Tuu Ward, Hanoi City

Những câu hỏi thường gặp

❖

Sản phẩm cùng loại khác