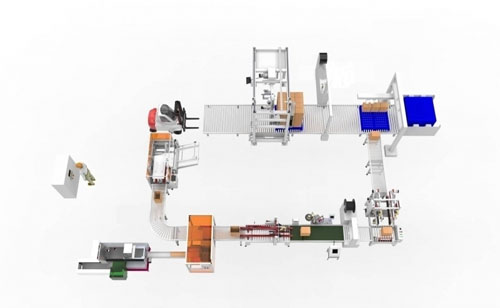

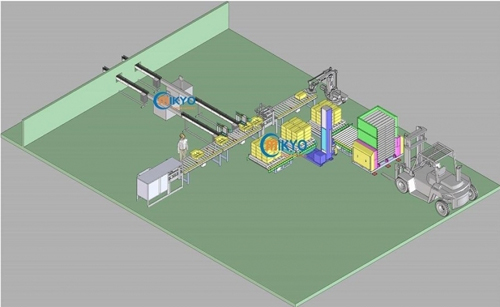

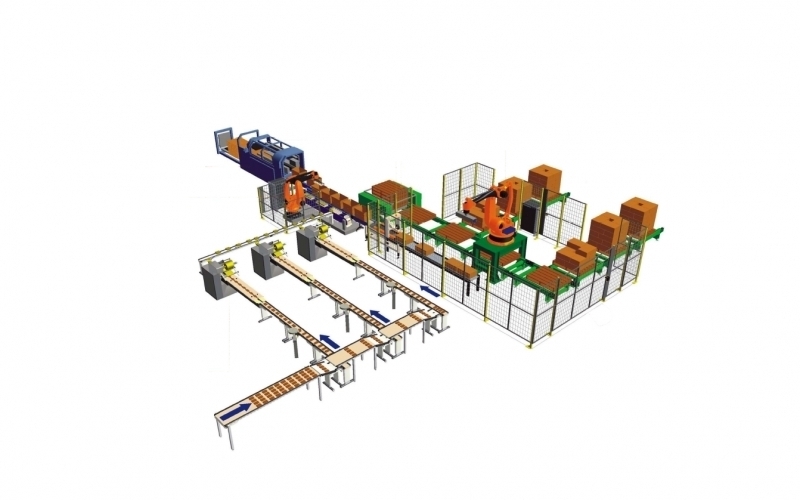

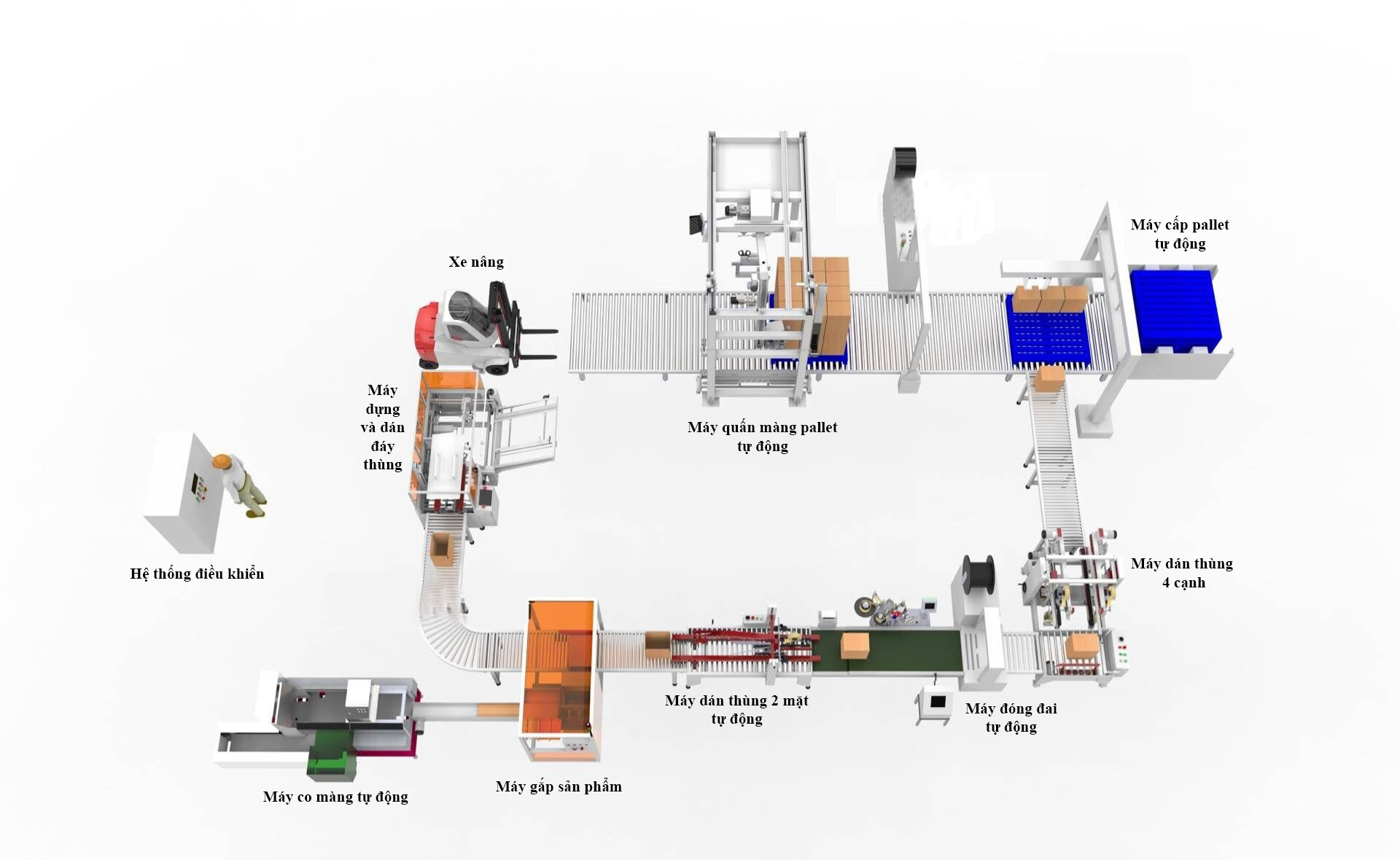

The automatic pallet strapping and packaging line is an integrated line of automatic packaging machines, suitable for all types of products and with fast processing speed. The line has a common control system, which is the PLC system and is displayed on the touch screen. Besides, the line is combined with an automatic pallet strapping machine, suitable for factories that need to pack goods firmly for export. And combining conveyors at desired speeds, palletizers reduce time and labor costs. The whole line only needs one person to observe the running process of the system and supply cartons, pallets, and PE films when the system reports. Also handle and catch basic errors when the system malfunctions.

![]()

Main specifications:

General activities

1, Finished products are transferred to the picking machine, and at the same time, the machine for erecting and gluing the bottom of the carton also follows the conveyor belt to the direction of the machine picking products into the carton.

2, The carton containing the product is transferred to the top sealing machine, each carton is fully packed.

3, Next, depending on the needs of each factory, the volume of the box will be weighed, labeled, stamped, and inkjet printed on the box. And using the way of gluing the 4 sides of the carton.

4, Then cartons are loaded onto pallets according to the quantity required by each factory.

5, According to the conveyor belt, the pallets are carefully strapped. And for automatic PE film wrapping. The line has been completed, the goods are transferred to the warehouse.

Device Information

We is always committed to using genuine equipment to ensure product quality, with an open warranty policy, we are committed to ensuring that your customer's line is always operating 24/24 and not stalled when there is a problem.

Main specifications:

| Item | Specifications |

| Packing speed | 10 thùng/phút ( Option: 8 , 10, 12, 16, 20 ) |

| Voltage | AC 220V/380 V / 50~60 Hz |

| Compressed air source | >500L/min , 0,4~0,8 Mpa |

| Product dimensions of belt machine | W1200 x H2000 mm |

| Barrel size | L200~500mm/W150~390mm/H100~350mm (Option: according to customer needs) |

| Pallet size | 1100x1100, 1200x1200,…. |

| Adhesive tape sizes | 36mm, 48mm, 50mm, 60mm |

| Line layout | Depending on customer factory layout |

| Total capacity | Depending on customer requirements |

General activities

1, Finished products are transferred to the picking machine, and at the same time, the machine for erecting and gluing the bottom of the carton also follows the conveyor belt to the direction of the machine picking products into the carton.

2, The carton containing the product is transferred to the top sealing machine, each carton is fully packed.

3, Next, depending on the needs of each factory, the volume of the box will be weighed, labeled, stamped, and inkjet printed on the box. And using the way of gluing the 4 sides of the carton.

4, Then cartons are loaded onto pallets according to the quantity required by each factory.

5, According to the conveyor belt, the pallets are carefully strapped. And for automatic PE film wrapping. The line has been completed, the goods are transferred to the warehouse.

Device Information

| Electrical Equipment | Brand |

| PLC | OMRON - Nhật Bản |

| Inverter | OMRON - Nhật Bản |

| Engine | Đài Loan |

| Sensor + Contactor | Schneider - Pháp |

We is always committed to using genuine equipment to ensure product quality, with an open warranty policy, we are committed to ensuring that your customer's line is always operating 24/24 and not stalled when there is a problem.

Những câu hỏi thường gặp

❖

Sản phẩm cùng loại khác