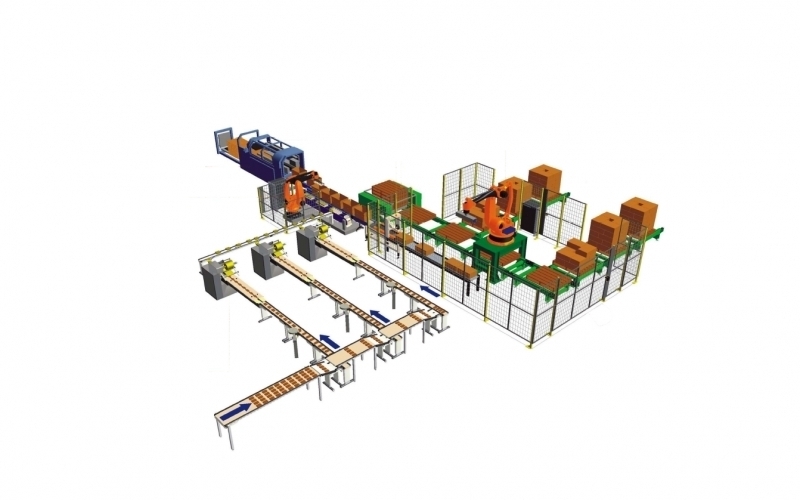

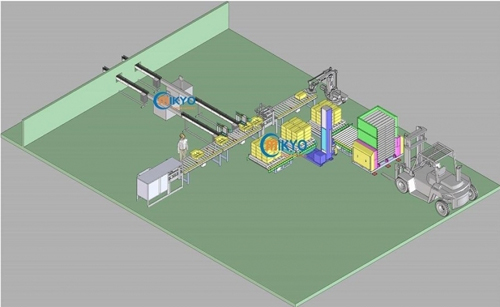

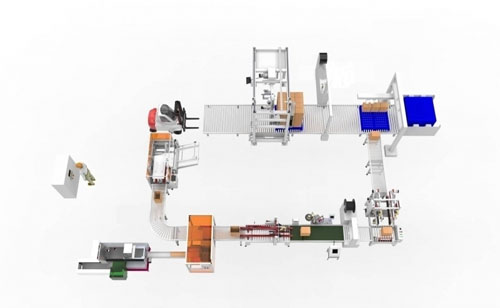

As the automation industry develops, the requirements for packaging are increasing. Therefore, the carton sealing line combined with the product picking robot helps to improve productivity, and the way goods are more and more aesthetically pleasing. The line is a combination of automation and programming machines according to an advanced PLC system. Help users optimize common errors and perfect automatic production machines. At the same time, the conveyor line can meet a variety of different types of packaged goods to help factories deal with all kinds of items.

![]()

Main specifications:

Overview of the chain

1. The line is designed with appropriate layout and equipment to ensure safety for users.

2. Using an automatic robot to ensure the accuracy of each rotation angle when picking up products and meeting many fast and slow time levels according to the self-conveyor goods input.

3. The line adopts PLC programming system, pneumatic control system combined with touch screen to maximize accuracy and reliability.

4. Fully automatic packaging machines for gluing, feeding and opening cartons. The robot automatically picks up the product into the carton and picks up the finished product on the pallet. At the same time, the pallet feeder automatically unloads the pallet according to the preset programming.

5. The touch screen can store the specifications of the products, no need to reset while the product changes.

6. The line is programmed closely, when an error is detected, it will be reported immediately for handling.

7. Packing diverse products according to the needs of customers.

Application

The line is widely used in the food, pharmaceutical, tobacco, beverage, chemical, toy, automobile, cable, electronic and other industries at home and abroad.

Mikyo will continuously improve the technical team to offer more automatic packaging solutions. Bringing customers high reliability, quality assurance and always ready to support customers when having problems, minimizing repair costs.

| Item | Specifications |

| Packing speed | 10 thùng/phút ( Option: 8 , 10, 12, 16, 20 ) |

| Voltage | AC 220V/380 V / 50~60 Hz |

| Compressed air source | >500L/min , 0,4~0,8 Mpa |

| Barrel size | L200~500mm/W150~390mm/H100~350mm (Option: according to customer needs) |

| Pallet size | 1100x1100, 1200x1200,….(mm) |

| Adhesive tape sizes | 36mm, 48mm, 50mm, 60mm |

| Line layout | Depending on customer factory layout |

| Total capacity | Depending on customer requirements |

| Machine noise | <80DB |

| Working table height | 600~800mm |

Overview of the chain

1. The line is designed with appropriate layout and equipment to ensure safety for users.

2. Using an automatic robot to ensure the accuracy of each rotation angle when picking up products and meeting many fast and slow time levels according to the self-conveyor goods input.

3. The line adopts PLC programming system, pneumatic control system combined with touch screen to maximize accuracy and reliability.

4. Fully automatic packaging machines for gluing, feeding and opening cartons. The robot automatically picks up the product into the carton and picks up the finished product on the pallet. At the same time, the pallet feeder automatically unloads the pallet according to the preset programming.

5. The touch screen can store the specifications of the products, no need to reset while the product changes.

6. The line is programmed closely, when an error is detected, it will be reported immediately for handling.

7. Packing diverse products according to the needs of customers.

Application

The line is widely used in the food, pharmaceutical, tobacco, beverage, chemical, toy, automobile, cable, electronic and other industries at home and abroad.

Mikyo will continuously improve the technical team to offer more automatic packaging solutions. Bringing customers high reliability, quality assurance and always ready to support customers when having problems, minimizing repair costs.

Những câu hỏi thường gặp

❖

Sản phẩm cùng loại khác