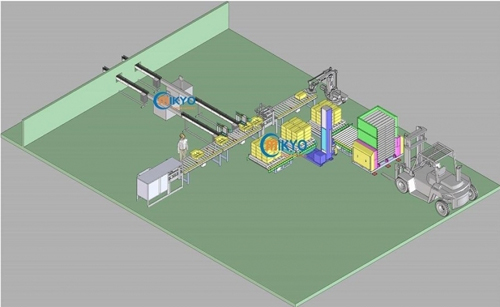

This automatic packaging system is exclusively for glass vials. More specifically, the glass jars inside are cucumbers, sauerkraut... They are exported, so they are very attentive to food safety issues. In addition, the system is integrated with a specialized product picking robot, meeting the requirements of the factory. At the same time, when the products are transferred and packed into the carton, the goods are automatically transferred to the pallet and wrapped in a fully automatic film. The combination helps goods to be shipped out quickly on schedule, not only that, but also helps to reduce product costs.

![]()

Specifications:

Device Information

- Fabrication materials: CT3, powder coating

- NCC pneumatic cylinder system: SMC, CKD

- Engine: Taiwan

- Robots: ABB, NACHI

![]()

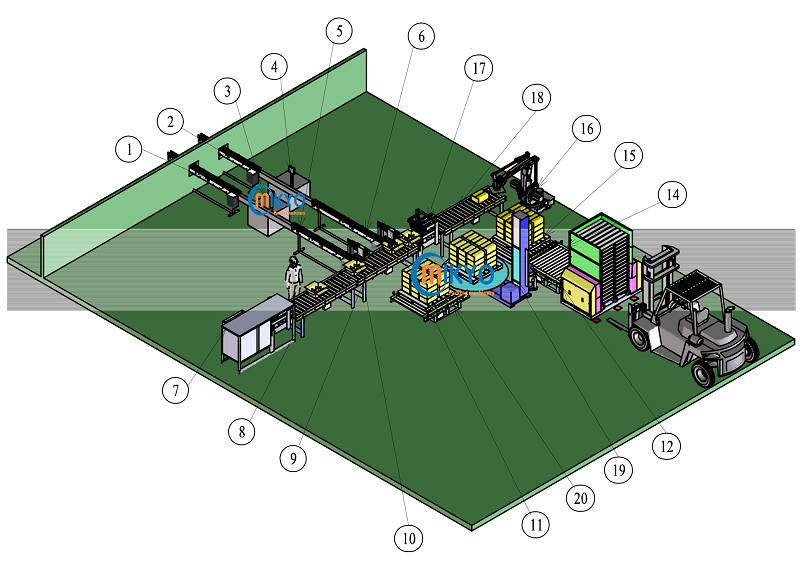

- Workers transport cartons to the assembly of machines to erect and glue the bottom of the box

- The bottom is glued and then goes through the STT8 conveyor, at this position, the worker will put the bottle divider into the empty box.

- The carton after being placed with the dividing plate will go through the conveyor No. STT9 and stop thanks to the stopper

- Two grippers (3 axes) pick up mussels from the conveyor No. STT5+6 and drop them into the bin

- After the container has filled with enough bottles as prescribed, go through the machine to glue the top side

- The barrel continues to pass through the conveyor No. STT18 and stops at the end position thanks to the stopper

- Robot puts crates on pallets placed on conveyor No. STT15 (number of boxes according to regulations)

- The pallet goes through the wrapping machine, then to the end conveyor No. STT20

- Forklift transports pallets wrapped in film to the specified place

- In addition, the system has an automatic pallet feeder:

+ Forklifts put empty pallets into the pallet dispenser

+ Pallets are distributed to the conveyor No. STT14+15 . in turn

- Glass bottle containing the product

+ After being closed, the product comes out through 2 conveyor belts STT1+2

+ Continue to go through 2 labeling machines

+ Bottles, after labeling, go through 2 conveyors STT5+6 and stop at the end of the conveyor, ready to be picked up and dropped into the bin.

Operation requirements

- Number of operating workers:

+ 01 worker put the carton into the machine to erect and glue the bottom of the box, put the dividing sheet into the box

+ 01 forklift operator puts pallets into the pallet dispenser machine cluster and transports the pallets containing the filmed containers to the specified gathering place

- Only works with one bottle size at a time, will adjust the system to work with the next series of other sizes

- Number of bottles in one pick up: 3 bottles

Mikyo will continuously improve the technical team to offer more automatic packaging solutions. Bringing customers high reliability, quality assurance and always ready to support customers when having problems, minimizing repair costs.

.png)

Specifications:

| Item | Specifications |

| Packing speed | 8 thùng/phút (Option: 8 , 10, 12, 16, 20) |

| Voltage | AC 220V/380 V / 50~60 Hz |

| Compressed air source | >500L/min; 0,4~0,8 Mpa |

| Barrel size | L200~500mm/W150~390mm/H100~350mm (Option: according to customer needs) |

| Pallet size | 1100x1100, 1200x1200,… |

| Adhesive tape sizes | 36mm, 48mm, 50mm, 60mm |

| Line layout | Depending on customer factory layout |

| Total capacity | Depending on customer requirements |

Device Information

- Fabrication materials: CT3, powder coating

- NCC pneumatic cylinder system: SMC, CKD

- Engine: Taiwan

- Robots: ABB, NACHI

Working principle

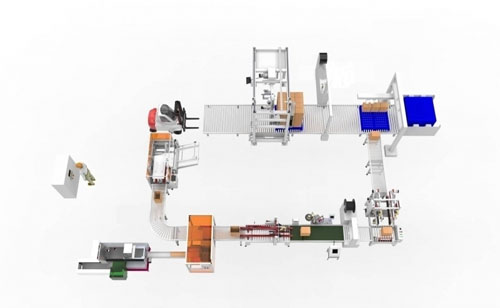

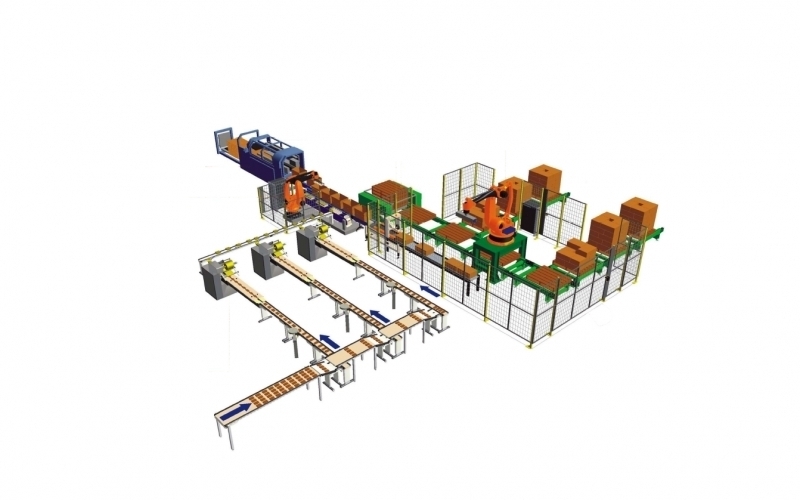

- Workers transport cartons to the assembly of machines to erect and glue the bottom of the box

- The bottom is glued and then goes through the STT8 conveyor, at this position, the worker will put the bottle divider into the empty box.

- The carton after being placed with the dividing plate will go through the conveyor No. STT9 and stop thanks to the stopper

- Two grippers (3 axes) pick up mussels from the conveyor No. STT5+6 and drop them into the bin

- After the container has filled with enough bottles as prescribed, go through the machine to glue the top side

- The barrel continues to pass through the conveyor No. STT18 and stops at the end position thanks to the stopper

- Robot puts crates on pallets placed on conveyor No. STT15 (number of boxes according to regulations)

- The pallet goes through the wrapping machine, then to the end conveyor No. STT20

- Forklift transports pallets wrapped in film to the specified place

- In addition, the system has an automatic pallet feeder:

+ Forklifts put empty pallets into the pallet dispenser

+ Pallets are distributed to the conveyor No. STT14+15 . in turn

- Glass bottle containing the product

+ After being closed, the product comes out through 2 conveyor belts STT1+2

+ Continue to go through 2 labeling machines

+ Bottles, after labeling, go through 2 conveyors STT5+6 and stop at the end of the conveyor, ready to be picked up and dropped into the bin.

Operation requirements

- Number of operating workers:

+ 01 worker put the carton into the machine to erect and glue the bottom of the box, put the dividing sheet into the box

+ 01 forklift operator puts pallets into the pallet dispenser machine cluster and transports the pallets containing the filmed containers to the specified gathering place

- Only works with one bottle size at a time, will adjust the system to work with the next series of other sizes

- Number of bottles in one pick up: 3 bottles

Mikyo will continuously improve the technical team to offer more automatic packaging solutions. Bringing customers high reliability, quality assurance and always ready to support customers when having problems, minimizing repair costs.

Những câu hỏi thường gặp

❖

Sản phẩm cùng loại khác