The strong development of automation systems is gradually replacing human labor. In particular, automatic packaging lines help increase productivity compared to traditional packaging techniques. Intech automatic packaging systems are designed and installed with continuous, stable operation processes and few errors in packaging.

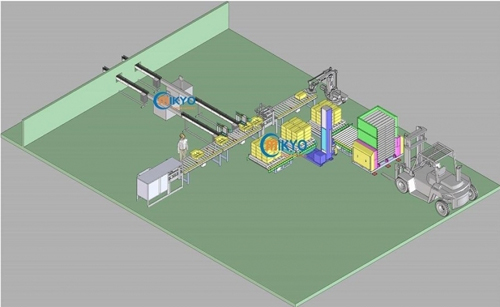

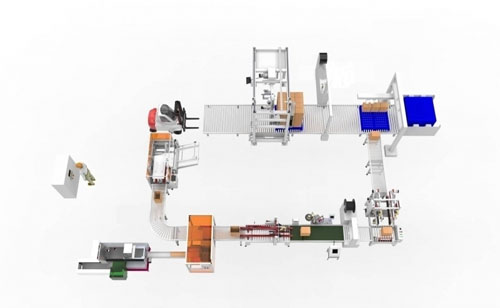

An automatic packaging system is a line with a sufficient number of automatic machines to sequentially perform product packaging stages and segments. Ensuring that the production and assembly process takes place continuously with optimal flow and efficiency. Packaging can be done by packaging machines or by industrial robot arms that load boxes, stack goods on pallets - automatic palletizers.

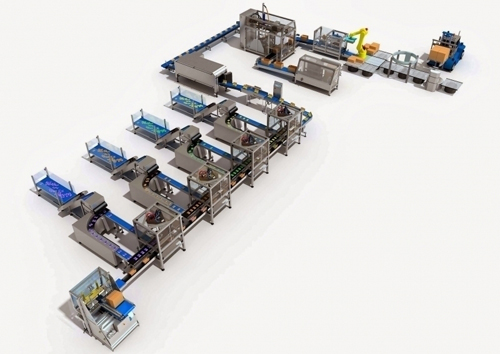

The automatic packaging line system includes automatic gift box feeding and opening machines, product picking machines, box picking robots, etc. The materials are transported sequentially through the lines, packaged meticulously and securely.

The gift box feeding and opening machine will automatically transfer the boxes along the conveyor belt to the product picking machines, then the boxes are transferred to the large picking machine to transfer the boxes into cartons and be completely packaged. The line is operated in a closed loop, helping to ensure technical requirements as well as product quality.

With a fully automatic system, it helps to significantly reduce the amount of labor on the production line. Using an automatic packaging line helps to optimize work, improve quality and minimize errors during the packaging process.

![]()

The automatic packaging line includes many types of combined packaging machines

Are you considering an automated packaging line but are unsure if the initial investment is worth it? While the initial cost of automated equipment may deter some businesses from investing in it, what they may not realize is that this initial cost is only a small fraction of the money they will save over time due to the benefits of automation.

If you are on the fence about an automated packaging line, here are 7 reasons why you should invest:

1. Consumer Demand

If you are seeing increased consumer demand and your packaging operations are struggling to keep up, it is time to consider automation. Your automated packaging line will allow you to produce more products in less time to meet demand.

2. Labor Costs

In manual packaging operations, labor is often the largest cost that can impact a business’ bottom line, with wages, high turnover, and injury lawsuits being the main drivers of overhead costs. Automation reduces labor costs by completing repetitive tasks, allowing you to reallocate that labor to other areas of your business.

3. Waste

Human error is often the main cause of material waste in packaging operations, as products need to be repackaged with more material when errors occur. On the other hand, automated equipment can reduce or eliminate these types of errors due to the high level of accuracy and consistency that manual operations cannot achieve. Reducing waste will also have a positive impact on your business’ carbon footprint, which is a growing concern for today’s consumers.

4. Quality Assurance

Human error can also have a negative impact on the quality of your product packaging. If an operator fails to spot a packaging error, this can lead to inconsistent quality, which can damage your product and damage your brand image. Automated equipment significantly reduces packaging errors, ensuring your packaging is done right the first time, every time.

5. Production Speed and Efficiency

Higher production speeds and increased efficiency are some of the common reasons businesses invest in automation solutions. It’s no secret that automated equipment completes tasks significantly faster than manual operators. Furthermore, automated equipment can also increase efficiency by performing multiple tasks – such as sealing and labeling a package in one go.

6. Health & Safety

In manual packaging operations, repetitive motion injuries are common and require employees to take time off to recover. By introducing automation into your packaging line, you are reducing the amount of hands-on work, ensuring employee safety, and reducing the costs associated with injuries.

7. Competition

Trends and challenges are changing the warehousing landscape, with many businesses saying they are planning to invest in new technology to stay competitive. Staying competitive in today’s on-demand economy is critical to your business’s success. Automated packaging technology ensures that you can improve response times and churn out products in larger quantities, giving you a competitive edge in an overcrowded market.

Here are some tips for integrating new equipment and using modern packaging automation solutions in your existing production line:

- Thorough assessment and planning

Before embarking on any upgrades, conduct a detailed assessment of your current packaging line. Assess the condition and capabilities of your current equipment and identify potential bottlenecks. Understanding your current system’s limitations will help you plan the most effective automation solutions.

- Deploy in phases

Deploying automation in phases is one of the best ways to reduce downtime and disruption. Instead of overhauling your entire system at once, upgrade in phases. This approach allows for a smoother transition, reduces the risk of significant downtime, and provides an opportunity to troubleshoot issues as they arise.

- Partner with experts

Partnering with a trusted packaging solutions provider like First Packaging Systems (FPS) is essential to a successful upgrade. FPS offers customized automation solutions tailored to the specific needs of your packaging line. Their team of experts can assist with everything from selecting compatible machinery to ensuring seamless integration with your existing systems.

- Ongoing Training and Support

Ensure your employees are fully trained on new equipment. FPS not only helps implement automated packaging systems, but also provides ongoing support and training. By ensuring your workforce is well prepared, you can maximize the benefits of automation while minimizing learning curves.

Automated packaging systems help increase productivity, reduce human error, save time and resources, and ensure product quality. They are commonly used in industries that produce mass products such as food, beverage, pharmaceuticals, and electronics.

At Intech, we provide efficient automated packaging line systems that ensure the final product is packaged reliably and of high quality. We will work with you to identify areas of your packaging operations that can be improved with the addition of automated technologies. Contact us today to get started, Hotline: 0918 808 795

What is an automatic packaging system?

An automatic packaging system is a line with a sufficient number of automatic machines to sequentially perform product packaging stages and segments. Ensuring that the production and assembly process takes place continuously with optimal flow and efficiency. Packaging can be done by packaging machines or by industrial robot arms that load boxes, stack goods on pallets - automatic palletizers.

Features of the automatic packaging system

The automatic packaging line system includes automatic gift box feeding and opening machines, product picking machines, box picking robots, etc. The materials are transported sequentially through the lines, packaged meticulously and securely.

The gift box feeding and opening machine will automatically transfer the boxes along the conveyor belt to the product picking machines, then the boxes are transferred to the large picking machine to transfer the boxes into cartons and be completely packaged. The line is operated in a closed loop, helping to ensure technical requirements as well as product quality.

With a fully automatic system, it helps to significantly reduce the amount of labor on the production line. Using an automatic packaging line helps to optimize work, improve quality and minimize errors during the packaging process.

The automatic packaging line includes many types of combined packaging machines

Why should you use an automatic packaging system?

Are you considering an automated packaging line but are unsure if the initial investment is worth it? While the initial cost of automated equipment may deter some businesses from investing in it, what they may not realize is that this initial cost is only a small fraction of the money they will save over time due to the benefits of automation.

If you are on the fence about an automated packaging line, here are 7 reasons why you should invest:

1. Consumer Demand

If you are seeing increased consumer demand and your packaging operations are struggling to keep up, it is time to consider automation. Your automated packaging line will allow you to produce more products in less time to meet demand.

2. Labor Costs

In manual packaging operations, labor is often the largest cost that can impact a business’ bottom line, with wages, high turnover, and injury lawsuits being the main drivers of overhead costs. Automation reduces labor costs by completing repetitive tasks, allowing you to reallocate that labor to other areas of your business.

3. Waste

Human error is often the main cause of material waste in packaging operations, as products need to be repackaged with more material when errors occur. On the other hand, automated equipment can reduce or eliminate these types of errors due to the high level of accuracy and consistency that manual operations cannot achieve. Reducing waste will also have a positive impact on your business’ carbon footprint, which is a growing concern for today’s consumers.

4. Quality Assurance

Human error can also have a negative impact on the quality of your product packaging. If an operator fails to spot a packaging error, this can lead to inconsistent quality, which can damage your product and damage your brand image. Automated equipment significantly reduces packaging errors, ensuring your packaging is done right the first time, every time.

5. Production Speed and Efficiency

Higher production speeds and increased efficiency are some of the common reasons businesses invest in automation solutions. It’s no secret that automated equipment completes tasks significantly faster than manual operators. Furthermore, automated equipment can also increase efficiency by performing multiple tasks – such as sealing and labeling a package in one go.

6. Health & Safety

In manual packaging operations, repetitive motion injuries are common and require employees to take time off to recover. By introducing automation into your packaging line, you are reducing the amount of hands-on work, ensuring employee safety, and reducing the costs associated with injuries.

7. Competition

Trends and challenges are changing the warehousing landscape, with many businesses saying they are planning to invest in new technology to stay competitive. Staying competitive in today’s on-demand economy is critical to your business’s success. Automated packaging technology ensures that you can improve response times and churn out products in larger quantities, giving you a competitive edge in an overcrowded market.

How to Integrate Automated Packaging Solutions?

Here are some tips for integrating new equipment and using modern packaging automation solutions in your existing production line:

- Thorough assessment and planning

Before embarking on any upgrades, conduct a detailed assessment of your current packaging line. Assess the condition and capabilities of your current equipment and identify potential bottlenecks. Understanding your current system’s limitations will help you plan the most effective automation solutions.

- Deploy in phases

Deploying automation in phases is one of the best ways to reduce downtime and disruption. Instead of overhauling your entire system at once, upgrade in phases. This approach allows for a smoother transition, reduces the risk of significant downtime, and provides an opportunity to troubleshoot issues as they arise.

- Partner with experts

Partnering with a trusted packaging solutions provider like First Packaging Systems (FPS) is essential to a successful upgrade. FPS offers customized automation solutions tailored to the specific needs of your packaging line. Their team of experts can assist with everything from selecting compatible machinery to ensuring seamless integration with your existing systems.

- Ongoing Training and Support

Ensure your employees are fully trained on new equipment. FPS not only helps implement automated packaging systems, but also provides ongoing support and training. By ensuring your workforce is well prepared, you can maximize the benefits of automation while minimizing learning curves.

Are you ready for an Automated Packaging System?

Automated packaging systems help increase productivity, reduce human error, save time and resources, and ensure product quality. They are commonly used in industries that produce mass products such as food, beverage, pharmaceuticals, and electronics.

At Intech, we provide efficient automated packaging line systems that ensure the final product is packaged reliably and of high quality. We will work with you to identify areas of your packaging operations that can be improved with the addition of automated technologies. Contact us today to get started, Hotline: 0918 808 795

Những câu hỏi thường gặp

❖

Sản phẩm cùng loại khác