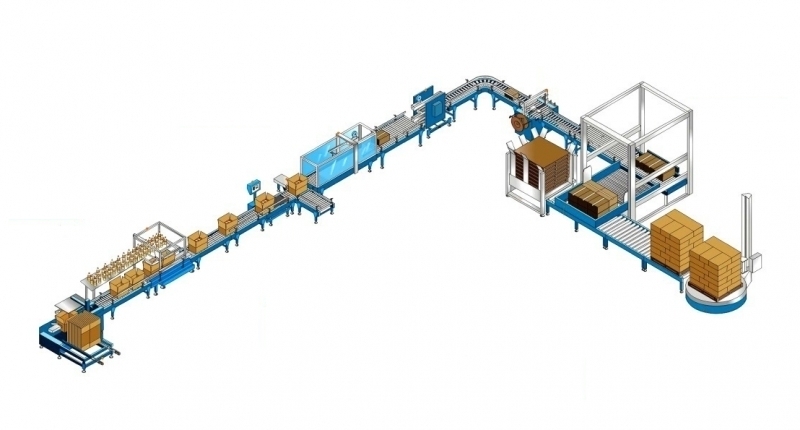

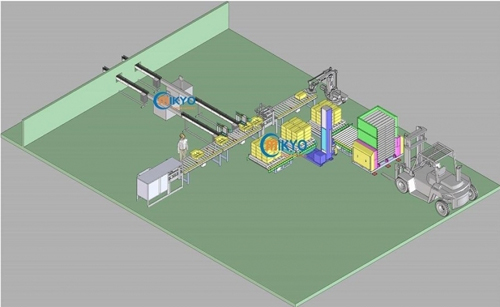

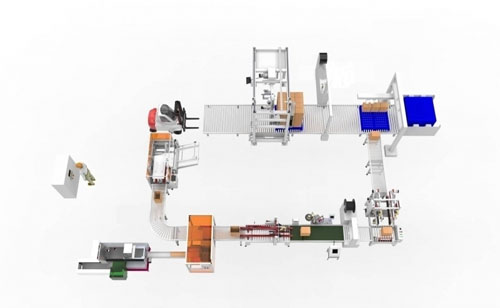

The automatic beverage packaging line is a line specifically designed for bottled beverage factories. The line is a combination of automatic packaging machines and an integrated weighing machine. The weighing machine helps the factory to accurately calculate the load of goods, avoiding the case of excess in production. And the line has an automatic pallet feeder to help reduce the time it takes to wrap goods for transport. In addition, the line is optimally designed in terms of packaging time and suitable layout for the factory's workshop.

![]()

The product is transported on a conveyor belt through a picker. At this time, the product is picked up into the carton and in the direction of the conveyor belt, it is transferred to the product weighing machine. Here, according to the pre-programmed product, the product will be weighed, the goods with insufficient weight will be shipped out. When the product has enough weight, it is forwarded to the top side sealing machine, then the 4 sides of the box are glued (depending on the packaging needs). Next is put through strapping to ensure the packing is secure. When receiving the signal that the box is finished strapping, the feeder will release the pallet according to the program to ensure that the product is loaded on the pallet according to the size and quantity requirements. Finally, load pallets with goods to switch to automatic film wrapping. Complete packaging line for shipping or storage.

We is always committed to using genuine equipment to ensure product quality, with an open warranty policy, we are committed to ensuring that your customer's line is always operating 24/24 and not stalled when there is a problem.

.png)

Main technical parameters

| Item | Specifications |

| Packing speed | 10 thùng/phút ( Option: 8 , 10, 12, 16, 20 ) |

| Voltage | AC 220V/380 V / 50~60 Hz |

| Compressed air source | >500L/min , 0,4~0,8 Mpa |

| Barrel size | L200~500mm/W150~390mm/H100~350mm (Option: according to customer needs) |

| Pallet size | 1100x1100, 1200x1200,… (mm) |

| Line layout | Depending on customer factory layout |

| Application of the line | Bottling into cartons |

| Working table height | 700~800mm |

General activities

The product is transported on a conveyor belt through a picker. At this time, the product is picked up into the carton and in the direction of the conveyor belt, it is transferred to the product weighing machine. Here, according to the pre-programmed product, the product will be weighed, the goods with insufficient weight will be shipped out. When the product has enough weight, it is forwarded to the top side sealing machine, then the 4 sides of the box are glued (depending on the packaging needs). Next is put through strapping to ensure the packing is secure. When receiving the signal that the box is finished strapping, the feeder will release the pallet according to the program to ensure that the product is loaded on the pallet according to the size and quantity requirements. Finally, load pallets with goods to switch to automatic film wrapping. Complete packaging line for shipping or storage.

Device Information:

| Electrical Equipment | Brand |

| PLC | Omron - Nhật Bản |

| Inverter | Omron - Nhật Bản |

| Engine | Taiwan |

| Sensor + Contactor | Schneider - Pháp |

We is always committed to using genuine equipment to ensure product quality, with an open warranty policy, we are committed to ensuring that your customer's line is always operating 24/24 and not stalled when there is a problem.

Những câu hỏi thường gặp

❖

Sản phẩm cùng loại khác