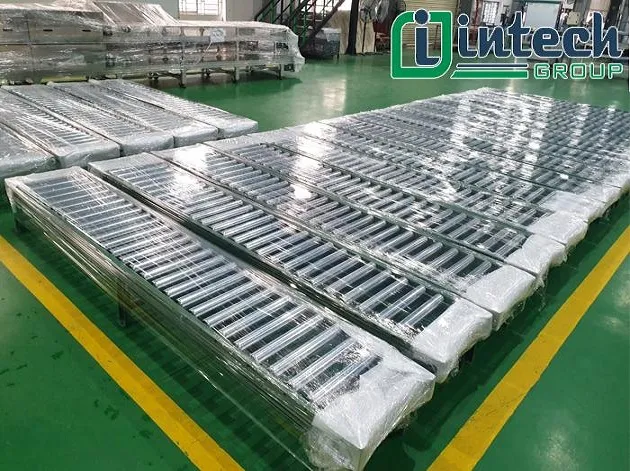

Free rollers conveyor

Rollers are a common cargo handling system in factories, warehouses and manufacturing facilities. The system consists of many rollers arranged in a row, forming a moving surface for the goods. Rollers can be designed in many different sizes, shapes and materials to suit specific types of goods and production requirements.

Roller structure:

A basic roller system includes the following components:

- Frame: Usually made of steel or stainless steel, forming the main structure of the roller system.

- Rollers: Are freely rotating round columns, made of materials such as steel, plastic or rubber.

- Surface: Is the part that directly contacts the goods, can be a flat surface or have grooves to position the goods.

- Motor (if any): Used to create thrust for the goods to move on the roller system.

Common types of rollers:

- Free rollers: No motor, goods move by thrust or gravity.

- Motorized rollers: Equipped with a motor to control the speed and direction of movement of goods.

- Collapsing rollers: Can adjust the length to suit the space and usage needs.

- Inclined rollers: Designed with a certain tilt to take advantage of gravity, helping goods move automatically.

-

![Flexible stacking rollers]()

Flexible stacking rollers

-

![Seamless industrial roller]()

Seamless industrial roller

-

![Seamless double roller]()

Seamless double roller

-

![Stainless Steel Roller Seamless]()

Stainless Steel Roller Seamless

-

![Seamless steel roller]()

Seamless steel roller

Những câu hỏi thường gặp