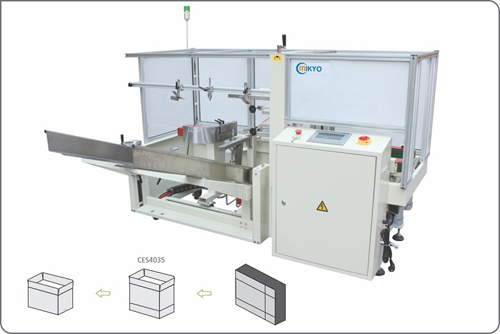

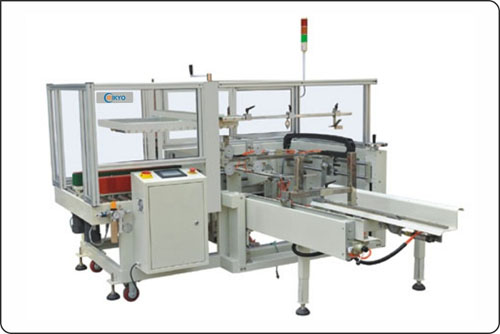

Carton Erector & Bottom Sealer Machine

The automatic carton bottom erecting and gluing machine is the first step in product packaging. The machine helps to shape and fold the carton tape at the bottom of the carton. The machine uses PLC and display screen to make the machine operate easier. Cartons are neatly stacked and put into the automatic bottom erecting and gluing machine quickly, saving time and labor costs.

This is an indispensable product in an automatic packaging line because automation helps to significantly increase labor productivity. At a reasonable cost, businesses can put carton folding and gluing machines into the production system to promote efficiency, improve production processes, and increase modernity in industrial production.

This is an indispensable product in an automatic packaging line because automation helps to significantly increase labor productivity. At a reasonable cost, businesses can put carton folding and gluing machines into the production system to promote efficiency, improve production processes, and increase modernity in industrial production.

What is a carton erecting machine?

A carton erecting machine is a type of packaging machinery designed to automate the process of forming and installing cartons or boxes. Its main function is to take empty cartons, fold them flat, and turn them into fully formed cartons ready for packaging. Large-sized adhesive tape is glued to the bottom of the carton smoothly, beautifully, and precisely. After the automatic carton erecting and gluing machine, the carton will be transferred to the next step of putting the product into the carton and being sealed with the top carton by another automatic carton sealing machine.

These machines play an important role in the packaging line, especially in industries where products are packaged in standard or custom-sized cartons.

Main parts of the Carton Erecting and Gluing Machine:

The carton erecting and gluing machine has a simple structure, compact design, easy to install and use. The machine can be adjusted to fold and glue the bottom of many different sized cartons.

- The feeding system is responsible for feeding flat cardboard blanks into the system. The blanks are usually pre-cut and creased, ready to be folded and shaped.

- The machine has a folding mechanism to fold and shape flat cartons into the desired box shape. This process involves precise folding and creasing to create a strong and well-shaped carton.

- The erecting mechanism ensures that the carton has its final shape and is ready for product insertion. This step is important to maintain consistency in carton dimensions and structural integrity.

The carton erecting machine comes with adjustable settings to accommodate different carton sizes.

Applications of Carton Erector and Sealer

- The machine is used to assemble cartons for packaging various food items such as cereals, snacks, frozen foods, ready meals and for beverage packaging.

- Applied in packaging of cosmetics and personal care items, such as skin care products, shampoos and toiletries.

- Used to package electronic devices and accessories into cartons.

- It plays a role in the automated packaging of products for e-commerce shipments, ensuring that items are securely packed in cartons for safe transportation.

- These machines can be used for custom and specialty packaging, accommodating unique shapes and sizes of products.

The versatility of Carton Erectors makes them a valuable asset in a variety of manufacturing and packaging environments.

How to choose the right carton erector and sealer?

Choosing the right carton erector for your specific needs can be a challenging task and therefore the following key factors will help you:

- Consider factors such as the type and size of cartons you will be working with, the volume of production, and the level of automation required.

- Semi-automatic machines require some manual intervention, making them suitable for smaller production lines. Fully automatic machines are more efficient and are ideal for large-scale operations.

- Different products may require different carton sizes. You need to ensure that the machine you choose can handle a variety of carton sizes and is easily adjustable. Flexibility in carton sizes accommodates changes in your product line and packaging requirements, providing long-term flexibility.

- Production speed is an important factor to consider. Evaluate the throughput capacity of the machine and compare it to your production needs. Consider both the maximum and average speed of the machine for optimal efficiency. Investing in a machine that matches or exceeds your capacity requirements will ensure smooth operations and prevent bottlenecks.

- Look for a machine that is user-friendly and easy to operate. Training time for your staff should be minimal and routine maintenance should be simple. A machine with easily accessible parts and clear documentation will help to streamline workflows and minimize downtime.

- The quality of the machine’s construction directly affects its overall longevity and reliability. Choose a machine that is built from durable materials that can withstand the demands of continuous production. This ensures a long-term return on investment and reduces the risk of unexpected breakdowns.

- If you already have a cartoning line, consider how a carton erector can integrate seamlessly with your existing systems. Compatibility with other equipment and the availability of custom options for integration are important factors in ensuring a cohesive and efficient production line.

- Prioritize workplace safety by choosing a machine with robust safety features. Make sure the machine complies with industry standards and regulations to create a safe working environment for operators.

Invest in a carton erector and sealer today to take packaging to the next level

Take the time to research and evaluate your options to ensure a reliable, efficient, and cost-effective carton erector and sealer solution for your packaging needs. Check out our machines, which excel at easily erecting and un-erecting boxes before they are filled, ensuring perfect setup even for the lightest boxes. Designed to integrate seamlessly into an automated packaging line, the machine offers a folding technique that ensures accuracy in the box assembly process. With the ability to set up thousands of boxes per day, our carton erecting and gluing machines are a comprehensive and reasonable packaging solution.

Contact to order:

In Hanoi: Lot 6, Lai Xa Industrial Park, Tay Tuu Ward, Hanoi City

Hotline: 0918 808 795 - Email: sales@mikyo.vn

-----

In Da Nang: No. 151 Bui Thien Ngo, Hoa Xuan Ward, Cam Le District, Da Nang City

Hotline: 0981 981 128 - Email: sales@mikyo.vn

-----

In Ho Chi Minh City: Lot B, Road No. 2A, Dong An Industrial Park, Binh Hoa Ward, Ho Chi Minh City

Hotline: 0918 000 267 - Email: sales.hcm@mikyo.vn

-

![CES5050 Strapping Machine]()

CES5050 Strapping Machine

-

![CES4035N/A Strapping Machine]()

CES4035N/A Strapping Machine

-

![GB30 Strapping Machine]()

GB30 Strapping Machine

-

![CES4035N Strapping Machine]()

CES4035N Strapping Machine

-

![CES5050A Strapping Machine]()

CES5050A Strapping Machine

Những câu hỏi thường gặp